| Size Range | 0.5-1000 µm |

| Objectives | 2.5X, 5X, 10X, 20X and 50X. |

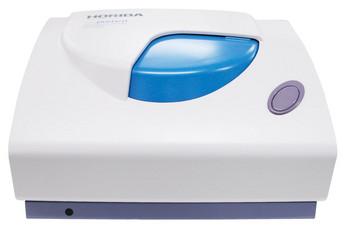

| Automation | Computer controlled Motorized nosepiece, Computer controlled Motorized condenser, Computer controlled Motorized focus, 0.05mic/step, Motorized stage 215 x 75 mm travel, 0.5 mic/step, CLEMEX Motorized stage controller assembly. |

| Measurement Time | Between 2 and 30 minutes depending on particle size and number of particles analyzed. |

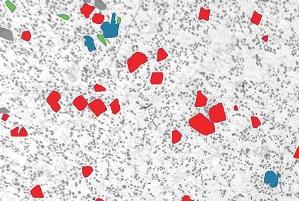

Principle of Operation

The use of automated image analysis is increasingly being recognized as an attractive technique to characterize particle shape and size distribution. Traditional methods, such as laser diffraction, although highly efficient, give limited information on particle shape proving image analysis as the best tool for performing particle analysis.

Accessories

Disperser Unit – An automated sample disperser subjects powder samples to a controlled quantity of force by subjecting the sample to a burst of air as a vacuum is released. The sample disperser breaks agglomerates and assures an even spread of sample across the slide. Unit includes disperser column, two slides base, high vacuum dry pump assembly, and USB computer control unit and software.