The creation of a meaningful and product-appropriate particle size specification requires knowledge of its effect on product performance in addition to an understanding of how results should be interpreted for a given technique. This section provides guidelines for setting particle size specifications on particulate materials—primarily when using the laser diffraction technique, but also with information about dynamic light scattering (DLS) and image analysis.

Different particle sizing techniques report primary results based on number, volume, weight, surface area, or intensity. As a general rule specifications should be based in the format of the primary result for a given technique. Laser diffraction generates results based on volume distributions and any specification should be volume based. Likewise, an intensity basis should be used for DLS specifications, volume for sieving or laser diffraction, and number for image analysis. Conversion to another basis such as number—although possible in the software—is inadvisable because significant error is introduced. The exception to this guideline is converting a number based result from a technique such as image analysis into a volume basis (ref. 1). The error involved is generally very low in this scenario.

While it is tempting to use a single number to represent a particle size distribution (PSD), and thus the product specification, this is typically not a good idea. In nearly every case, a single data point cannot adequately describe a distribution of data points. This can easily lead to misunderstandings and provides no information about the width of the distribution. Less experienced users may believe that the “average particle size” can adequately describe a size distribution, but this implies expecting a response based on a calculated average (or mean). If forced to use a single calculated number to represent the mid-point of a particle size distribution, then the common practice is to report the median and not the mean. The median is the most stable calculation generated by laser diffraction and should be the value used for a single point specification in most cases.

Rather than use a single point in the distribution as a specification, it is suggested to include other size parameters in order to describe the width of the distribution. The span is a common calculation to quantify distribution width: (D90 – D10) / D50. However, it is rare to see span as part of a particle size specification. The more common practice is to include two points which describe the coarsest and finest parts of the distribution. These are typically the D90 and D10. Using the same convention as the D50, the D90 describes the diameter where ninety percent of the distribution has a smaller particle size and ten percent has a larger particle size. The D10 diameter has ten percent smaller and ninety percent larger. A three point specification featuring the D10, D50, and D90 will be considered complete and appropriate for most particulate materials.

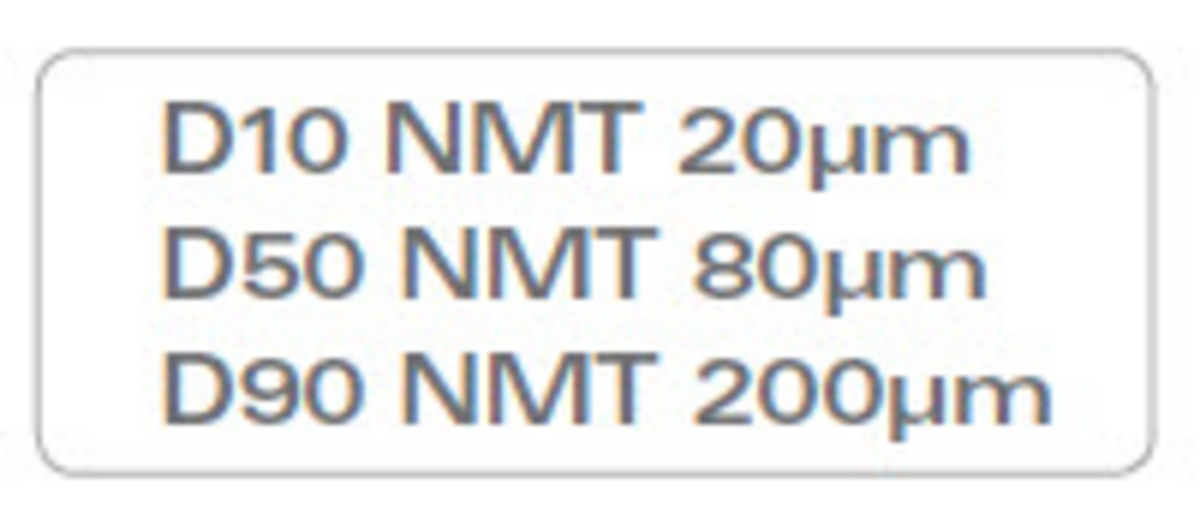

How these points are expressed may vary. Some specifications use a format where the D10, D50, and D90 must not be more than (NMT) a stated size.

Although only one size is stated for each point there is an implied range of acceptable sizes (i.e. the D50 passes if between 20 and 80μm).

Alternatively, a range of values can be explicitly stated.

This approach better defines the acceptable size distribution, but may be perceived as overly complicated for many materials.

It may also be tempting to include a requirement that 100% of the distribution is smaller than a given size. This implies calculating the D100 which is not recommended. The D100 result (and to a lesser degree the D0) is the least robust calculation from any experiment. Any slight disturbance during the measurement such as an air bubble or thermal fluctuation can significantly influence the D100 value. Additionally, the statistics involved with calculating this value (and other “extreme” values such as the D99, D1, etc.) aren’t as robust because there may not be very many of the “largest” and “smallest” particles. Given the possible broad spread of D100 results it is not recommended for use in creating specifications involving a statement that 100% of the particles are below a stated size.

Ultimately, the sophistication of the specification should be driven by how particle size influences product performance. Given that some people ask about the “average size”, it is not surprising that some specifications are based on a mean diameter. This approach is complicated by the fact that there are several mean values that can be calculated and reported in the result (ref. 2). The most common mean value noted when using laser diffraction is the volume mean, or D4,3. The D4,3 is very sensitive to the presence of large particles in the distribution. It is a good idea to use or include the D4,3 in the specification if product performance is sensitive to the presence of large particles. The other mean value occasionally used is the D3,2, or surface mean. This value is only typically used when the product is an aerosol or spray.

Figure 1: Error appears exaggerated on the Y axis because of the narrowness of the PSD.

Other published specifications are based on the percent below a given particle size such as: 50% below 20μm and 90% below 100μm. This type of specification is based on points along the y axis (which reports frequency percent) as opposed to the x axis (which reports diameter) as in the previous examples. Although this approach has been used in many specifications, it is important to realize the difference between using the x (size) and y (percent) axes. All measurements include an error which should always be considered when setting a specification.

For the example shown in Figure 1, the D50 is 100μm with an error of +/- 5% on the x (size) axis. This error includes all sources such as sampling and sample preparation. The same error becomes +/- 20% when translated to the y (percent) axis. Stating an error of +/- 5% is more attractive than +/- 20%, even when expressing the same actual error range. The degree to which the y axis error is exaggerated vs. the x axis depends upon the steepness of the distribution curve.

Figure 2: In this example, percentage of the PSD is reported at 100 nm.

There are applications where the percent below a given particle size is an important result. Recently there has been interest in the presence of “nanoparticles” (at least one dimension smaller than 100nm) in products such as cosmetics. The software which calculates the PSD should be capable of easily reporting the percent under any chosen size—in this case the percent below 100nm (Figure 2). In the LA-960 software this is displayed as “Diameter on Cumulative %”. In the example below the value for percent less than 100nm is reported as 9.155%.

Several points are worth mentioning in regards to setting a specification on the percent below 100nm as in this example specifically and for sub-micron materials generally. The particle size distribution is dependent upon many factors including the sample preparation method. The laser diffraction technique works best within a certain particulate concentration range. This sometimes requires that samples undergo dilution. In some cases this dilution may change the state of the particles and affect the apparent size distribution. Additionally, ultrasonic energy can be applied to improve the dispersion of agglomerates which can significantly change the result.

There are currently two internationally accepted standards written on the use of laser diffraction: ISO 13320 (ref. 3) and USP<429> (ref. 4). Both standards state that samples should be measured at least three times and reproducibility must meet specified guidelines. Note that this means three independent measurements (i.e. prepare the sample, measure the sample, empty the instrument, and repeat). The coefficient of variation (COV, or (std dev/mean)*100) for the measurement set must be less than 3% at the D50 and less than 5% at the D10 and D90 to pass the ISO 13320 requirements. These guidelines change to less than 10% at the D50 and less than 15% at the D10 and D90 when following the USP<429> requirements. Finally, the guidelines all double when the D50 of the material is less than 10μm.

While following the ISO or USP guidelines to test reproducibility is suggested, it is typically part of an internal specification or procedure. The specifications shown to potential customers typically don’t include the reproducibility values.

Figure 3: If the total measurement error is +/- 10%, then the specification must be tightened in order to assure the product stays within performance specification.

The reproducibility errors discussed above should be investigated and minimized because they play an important role in the final setting of a specification. Once the specification based on product performance has been determined, then the final specification must be narrowed by the error range (ref. 5). In the example shown in Figure 3 the specification for the D50 is 100 +/- 20% (or 80–120 μm) based on product performance. If the total measurement error is +/- 10% (using USP<429> guidelines for the D50 value), the specification must be tightened to ~90–110 μm (rounded for simplicity) in order to assure the product is never out of the performance specification. For example, if the D50 is measured to be 110 μm, we are certain the D50 is actually less than 120 μm even with a maximum 10% error.

This is why it is important to create robust standard operating procedures for any material we wish to set a published specification for. Any combination of high measurement error (usually stemming from non-optimized method development) and tight specifications will make meeting that specification more difficult. Why make life harder than it need be?

The primary results from dynamic light scattering (DLS) systems are typically reported as an intensity distribution. Key values included in DLS-based specifications are the intensity-weighted average (often called the z average) and the polydispersity index (PI), which quantifies distribution width. Mean values for one or more peaks can be calculated and included in the results. The results can be transformed into a volume-based or number-based distribution when comparing to other techniques such as laser diffraction or microscopy.

The primary result reported by image analysis is a number distribution since the particles are inspected one at a time. Setting specifications based on the number distribution is acceptable, but this is the one example where conversion to another basis (i.e. volume) is both acceptable and often preferred. As long as a sufficient number of particles are inspected to fully define the distribution, then the conversion from number to volume does not introduce unknown errors into the result. The pharmaceutical industry discussed the subject at a meeting organized by the AAPS (ref. 6) and concluded that results are preferably reported as volume distributions.

Particle size distribution specifications based on the image analysis technique often include the mean, D10, D50, and D90 values. Care should be taken to avoid basing specifications on the number-based mean since this value may not track process changes such as milling or agglomeration (ref. 7). Conversion from number to volume distribution can be performed with high accuracy by specifying the typical particle shape (spherical, cylindrical, ellipsoidal, tetragonal, etc.).

Particle shape parameters such as roundness, aspect ratio, and compactness are used to describe particle morphology. Specifications for shape parameters are typically reported using just the number-based mean value, so this is recommended for setting specifications.

The task of setting a particle size specification for a material requires knowledge of which technique will be used for the analysis and how size affects product performance. Sources of error must be investigated and incorporated into the final specification. Be aware that, in general, different particle sizing techniques will produce different results for a variety of reasons including: the physical property being measured, the algorithm used, the basis of the distribution (number, volume, etc.) and the dynamic range of the instrument. Therefore, a specification based on using laser diffraction is not easily compared to expectations from other techniques such as particle counting or sieving. One exception to this rule is the ability of dymanic image analysis to match sieve results.

Attempting to reproduce PSD results to investigate whether a material is indeed within a stated specification requires detailed knowledge of how the measurement was acquired including variables such as the refractive index, sampling procedure, sample preparation, amount and power of ultrasound, etc. This detailed information is almost never part of a published specification and would require additional communications between the multiple parties involved.

Granulomètre par diffusion laser

Simultaneous Multi-Laser Nanoparticle Tracking Analysis (NTA)

Direct Imaging Particle Analyzer

Dynamic Image Analysis

Analyseur de nanoparticules

Analyseur de nanoparticules à centrifugation

Granulomètre par diffusion laser

Static Image Analysis System Particle Size

BET Flowing Gas Surface Area Analyzers

BET Surface Area Analyzers

Do you have any questions or requests? Use this form to contact our specialists.