Particle Detection System

HORIBA’s Particle Detection and Removal systems are essential to improving yield in the semiconductor lithography process. These systems detect particles on a reticle/mask with high reliability and long-term stability. The systems can measure particles on each glass/pellicle surface with precision and high throughput contributing to yield improvements for any semiconductor manufacturing facility.

PD Xpadion is a fully-automated laser scattering based particle detection system designed to detect, analyze, and capture images of surface particulates on reticle/photomask in mask shops. In addition to particle detection, PD Xpadion is designed to implement particle characterization by Raman analysis, pellicle film thickness and uniformity, and pellicle health monitoring tools.

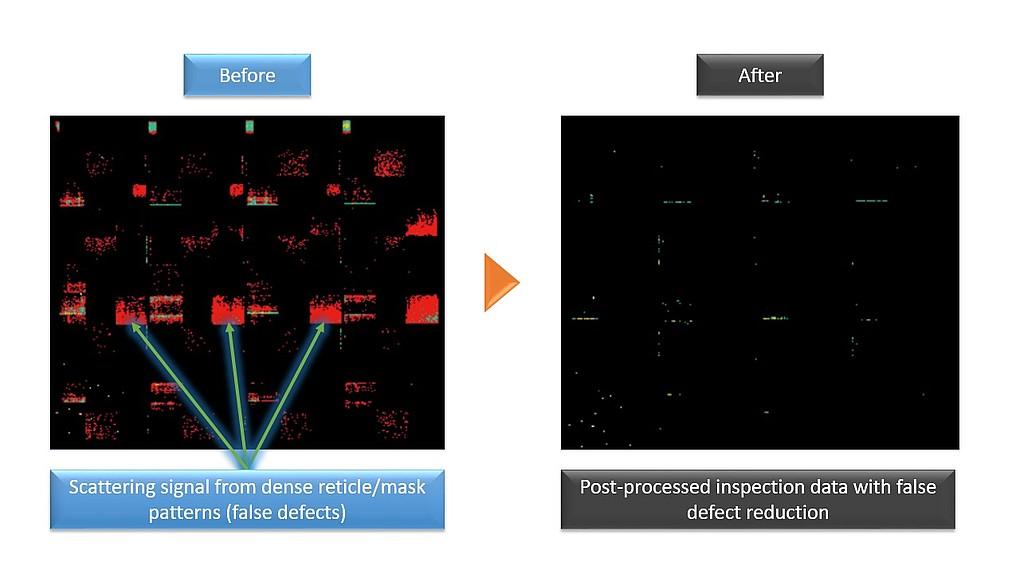

PD Xpadion has an advantage over built-in type particle inspection units, it can detect particles on pellicle/glass surface without any false detection.

![]()

Information Obtained: Particle detection and location / particle size and particle image / particle material analysis (raman analysis)

![]()

PD Xpadion: automatic or manual / particle sizing tools for advanced analysis

Camera Endpoint Monitor based on Real Time Laser Interferometry

Reticle / Mask Particle Detection System

Reticle/Mask Particle Remover

X-ray Analytical Microscope

with a Super Large Chamber

Add Spectroscopy to ANY Microscope

Do you have any questions or requests? Use this form to contact our specialists.