- Multi gas monitoring (Supported SiF4 andCF4) (IR-422)

- High sensitivity

- Gas cell heating function up to 180 dec.C

- Multi-display

- Analog/Digital communication.

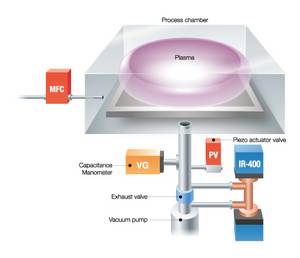

Benefits of real-time end-point monitoring with the IR-400

- Reduce time for chamber cleans

- Reduce usage of cleaning gases

- Repeatable and predictable clean process

- Longer lifetime of chamber components

Applications example

- Monitoring chamber exhaust line

Measurement Techniques

Reliable, High-performance

Non-dispersive Infrared Absorptiometry (NDIR)

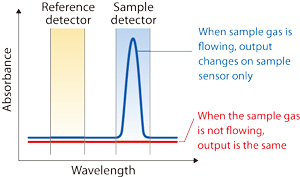

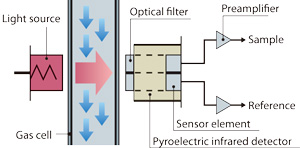

The infrared absorptiometry method employed by the IR-300 Series uses the principle of the absorption by gas molecules of the infrared light emitted from an infrared light source. A sample output from a sample that has absorbed the gas being measured is compared to a reference output with no absorbance, and the result is converted into a gas concentration. The use of this double beam method enables long-term, stable measurement results to be obtained.

The optical system is made up of a light source, gas cell and double beam detectors. The stability of the double beam detector has been proven over a period of more than 40 years.

![]()