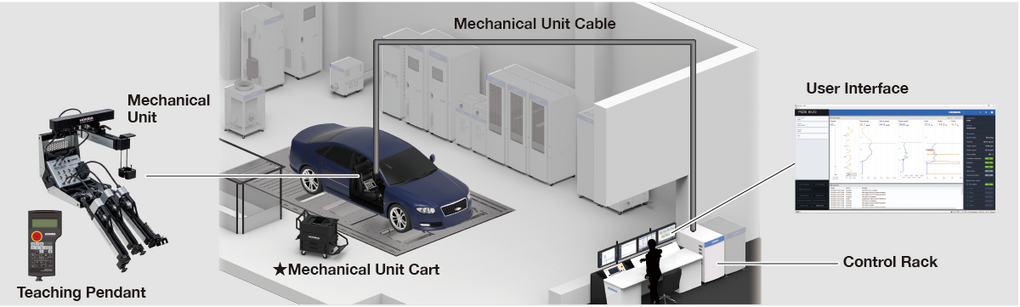

Basic Functions

| Driving Functions | Standard drive traces (emissions, etc) ★Performance test mode Auto/Manual adjust (pedal and shift) Learning mode Warm up mode Constant speed mode Manual mode |

|---|---|

| Applicable Vehicles | MT, AT, CVT, ★Hybrid/EV Floor shift, ★Instrument panel shift, ★Column shift For both left and right hand drive vehicles |

| Other Functions | Measurement function:Dynamometer speed, Engine speed External operation input : Drive start/stop External condition input : Dynamometer ready/error,Blower ON External operation output : Synchronization signal with data processing device ★HOST communication:AK compliant |

Specifications

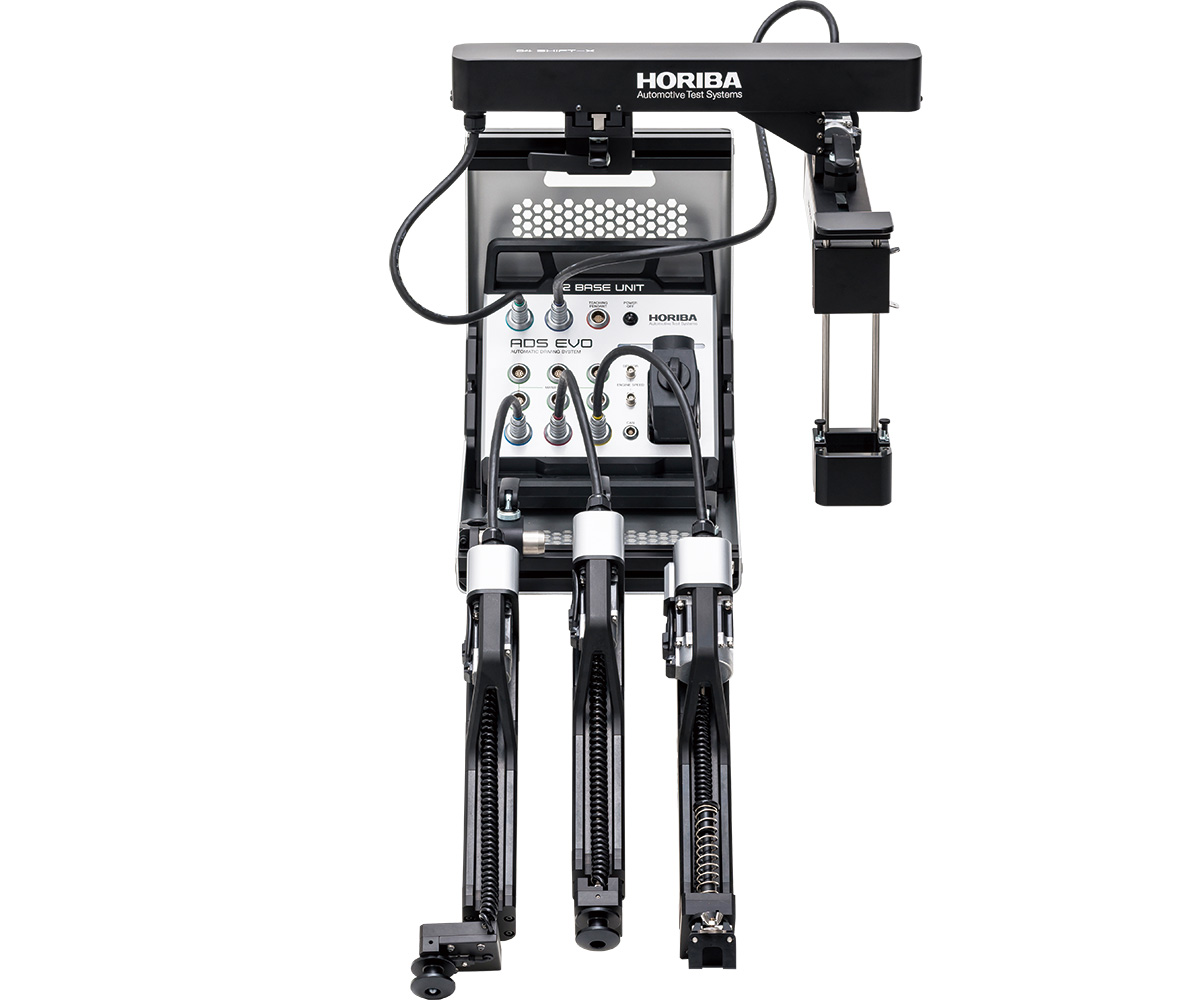

| Mechanical Unit | |

|---|---|

| Total Mass | Standard Specification : 30 kg |

| Unit Mass | 3 - 7 kg |

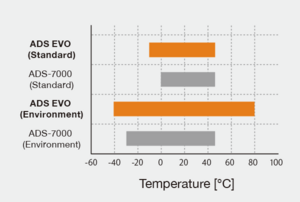

| Operating Environment | Standard Specification: -10 - 45℃ 30 - 90%RH(no condensation) ★Environment Resistance Specification : -40 - 80℃ 30 - 90%RH(no condensation) |

| Actuators | Accelerator:Stroke length 150 mm, Rated output 160 N, Maximum operating speed 0.61 m/s Brake:Stroke length 200 mm, Rated output 241 N, Maximum operating speed 0.61 m/s Clutch:Stroke length 200 mm, Rated output 322 N, Maximum operating speed 0.78 m/s Shift(X):Stroke length 190 mm, Rated output 193 N, Maximum operating speed 0.77 m/s Shift(Y):Stroke length 240 mm, Rated output 193 N, Maximum operating speed 0.77m/s Starter(PUSH):Rated output 16 N ★Starter(TURN):Rated output 0.97 N・m ★Up to 5ch push actuators can be added |

| Control Rack | |

|---|---|

| Size | 578(W) × 929(D) × 1000(H) mm |

| Operating Environment | 5 - 40℃ 20 - 80%RH(no condensation) |

| Power supply | Single phase:AC 200 - 240 V ± 10% (Max 250 V) 50/60 Hz 3.0 kVA or Single phase:AC 100 - 120 V ± 10% 50/60 Hz 3.0 kVA |

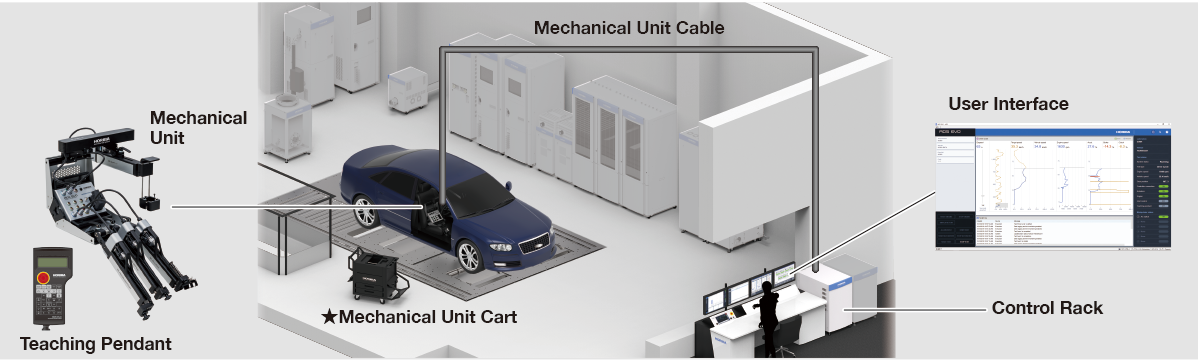

| Others | Teaching pendant:Used for learning shift positions and other various settings Mechanical unit cable:Connect mechanical unit and control rack |

★: Option