IRLAM Overview

IRLAM's features of High Sensitivity, Low Interference, Compact size and High Reliability are also realized by its unique hardware configuration.

The optical system of an infrared gas analyzer consists of an infrared light source, a gas cell, and a detector. Of these, HORIBA has newly developed the Quantum Cascade Laser (QCL) as the infrared light source and the Herriott Cell (multi-pass cell) as the gas cell to adopt them as the optical system of the IRLAM. In order to manufacture high performance analyzers, all of IRLAM's optical systems are designed and manufactured in-house by highly skilled engineers, and are subject to thorough quality control.

Basic configuration of the optical system of IRLAM analyzer

Basic configuration of the optical system of IRLAM analyzer

Many gases show the strongest absorption in the mid-infrared region of the spectrum. The Quantum Cascade Laser (QCL), which can emit light in the mid-infrared region (4 - 10 µm), are considered to be the most suitable light source for gas analysis. Since the wavelength range of QCL light is very narrow, it is possible to pinpoint the wavelength absorbed by the target gas while avoiding the influence of interfering gases.

As a result, QCL can achieve much higher precision and sensitivity than other light sources.

The QCL can change the oscillation wavelength and is freely designed according to the structure of the semiconductor thin film that constitutes the laser element. Since the oscillation wavelength changes sensitively depending on the temperature of the laser element, by precisely controlling the temperature with a Peltier element built in the package, the QCL can precisely oscillate at the targeted wavelength.

The gas components to be measured and the test conditions vary from customer to customer. Since HORIBA develops and manufactures the QCLs that oscillate at the optimum wavelength for each application in-house, it can provide optimized gas analyzers with response flexibility to diverse needs.

HORIBA's QCL is designed specifically for gas measurement, and has unique innovations (Patent pending) to minimize optical interference noise and oscillation wavelength shift due to ambient temperature change, which are issues unique to gas analysis using lasers.

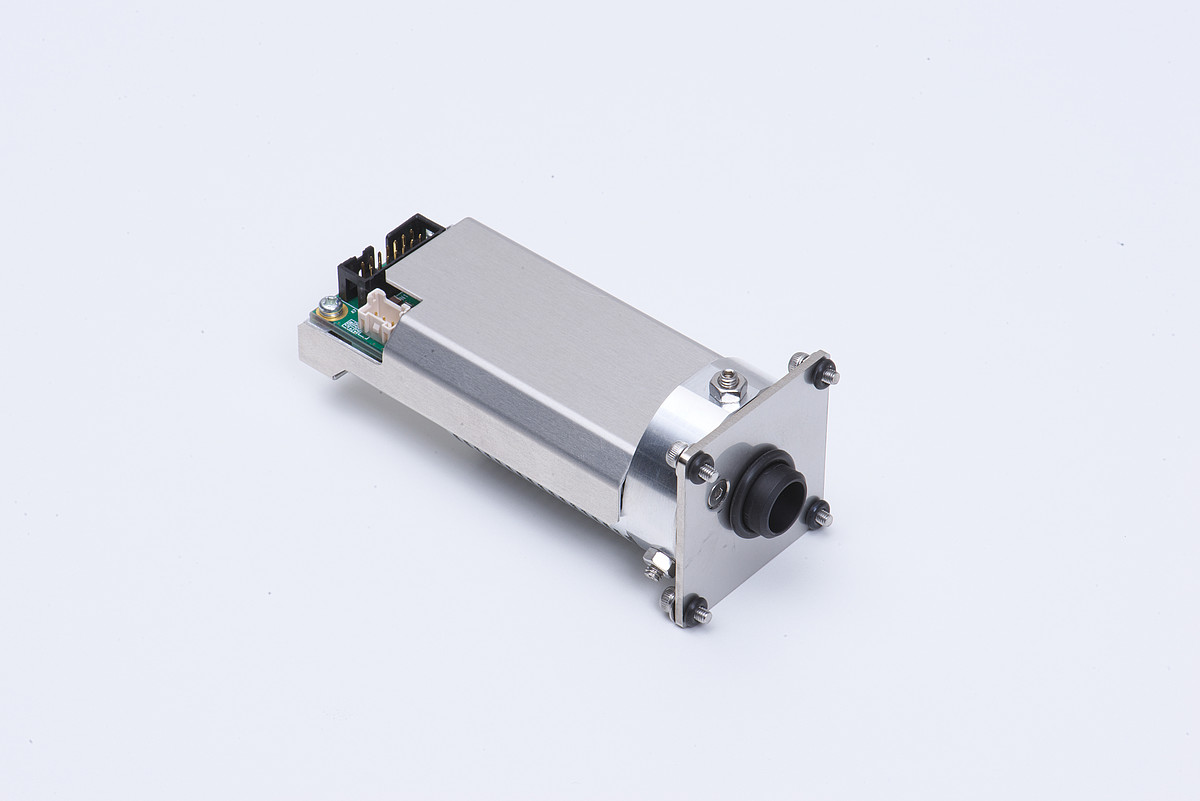

QCL Element

QCL Module

The amount of gas absorption increases in proportion to the length of the optical path length (the distance the light travels) of the infrared light passed through the gas cell. The longer the optical path length, the more sensitive the measurement becomes, and thus the lower the gas concentration can be measured.

Relationship between optical path length and signal magnitude

Relationship between optical path length and signal magnitude

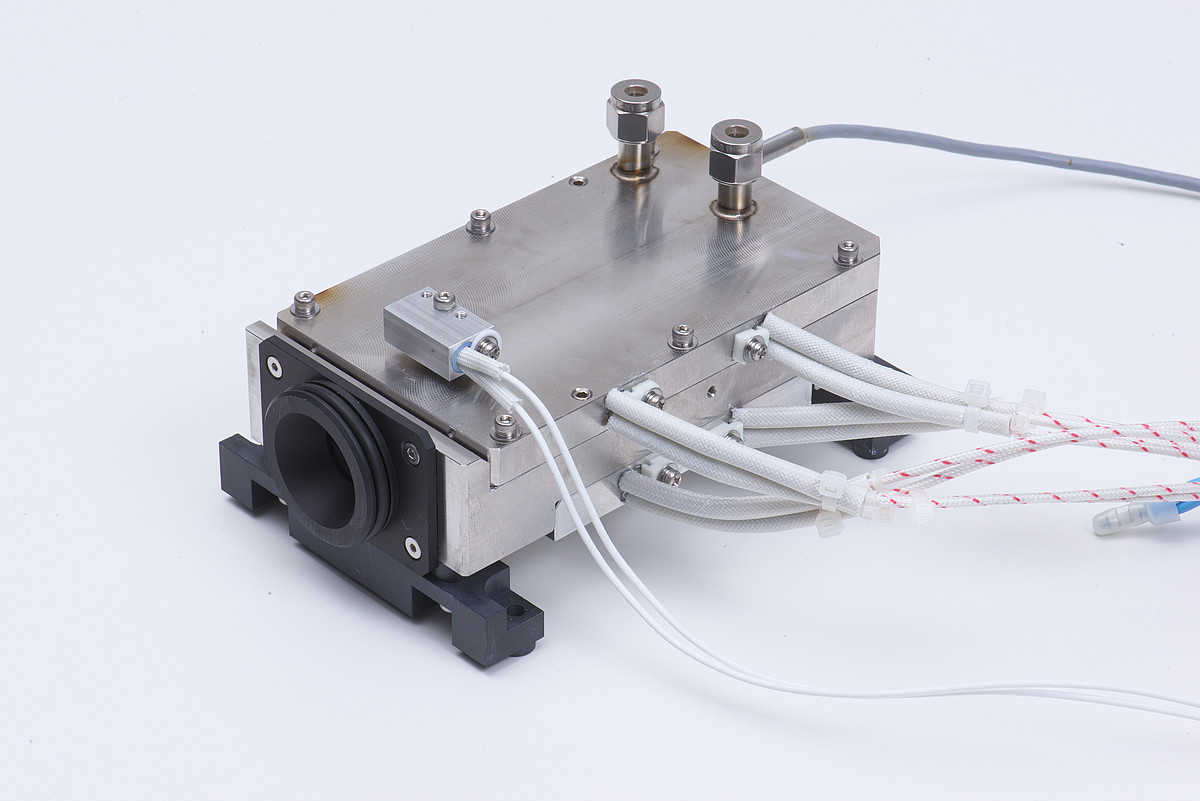

The IRLAM Herriott Cell, is two concave mirrors are arranged opposite to each other. By taking advantage of the laser's strong intensity and its nature to travel straight over long distances, and by reflecting the laser multiple times between the two mirrors, an optical path length of more than 5 meters can be obtained, and at the same time, the gas cell can be made smaller by devising the design of the mirrors (Patented (US Patent No. 10551299)).

HORIBA's Herriott Cell has improved responsiveness due to its compact size, which enables high-speed measurement even when the gas flow rate is low. Also, due to its robust design that resists vibration and shock, a wide range of applications can be expected, including fields that require portability and responsiveness.

Basic Structure inside Herriott Cell

Appearance of Herriott Cell

For more than 65 years, HORIBA has continued to refine its infrared gas analysis technology, called Non-Dispersive InfraRed absorption method (NDIR), and has delivered high-precision gas analyzers to the world. However, with the recent tightening of environmental standards and the increasing sophistication of industry, the performance required of gas analyzers has become increasingly diverse, and it has become difficult to meet customer needs with NDIR technology alone. This is why we focused on QCL: It has the potential to create analyzers with an accuracy that is an order of magnitude higher than that of conventional NDIR. We thought it must be the technology that can break through the limitations.

First, HORIBA started by making this QCL available for in-house production; it decided that it was essential to freely adjust the oscillation wavelength of the QCL in order to support the various gas analyzers HORIBA offers, and that we had no choice but to produce it in-house. In fact, HORIBA has produced its own Pneumatic detectors and optical filters, which are the most important components that affect the performance of NDIR. We decided to embrace the spirit of "making core components in-house", which is one of the reasons why HORIBA is able to deliver high-quality analyzers to the world, in QCL as well. QCL requires advanced semiconductor manufacturing equipment and manufacturing technology, which had to be created from scratch. The excitement when the prototype QCL glowed for the first time after much effort. About 10 years later, we have completed a new infrared gas analysis technology called IRLAM using QCLs.

In addition to the QCL as a light source, the key component of IRLAM is a dedicated Herriott Cell that creates a long optical path length. This unique Herriott Cell was also designed in-house. In order to improve the response time, the volume inside the cell is made as small as possible. With the three pillars of IRLAM technology, QCL, Herriott Cell, and Concentration Calculation Algorithm, this gas analysis technology promises extremely high potential for the future of gas analysis with IRLAM.

Do you have any questions or requests? Use this form to contact our specialists.