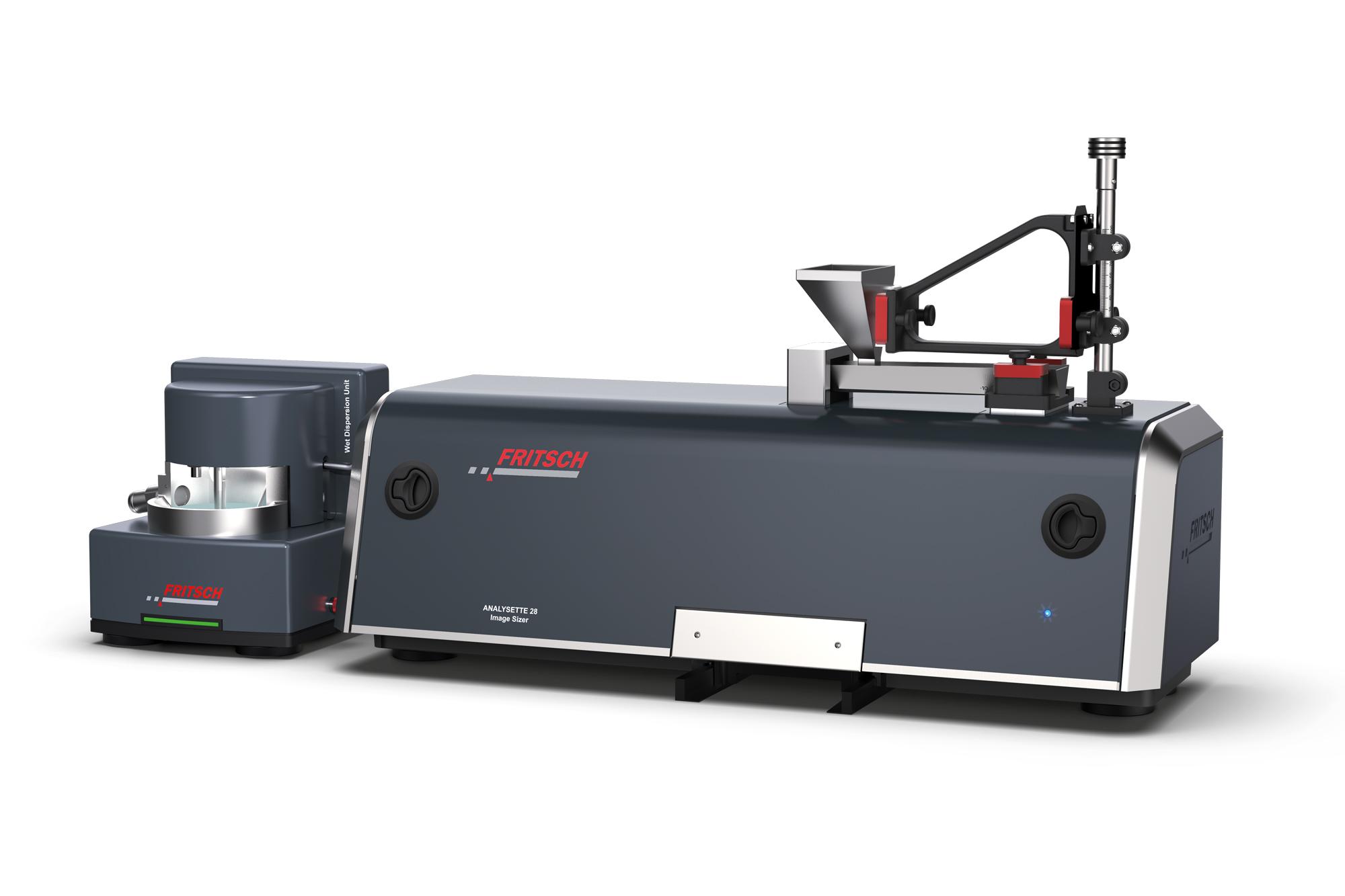

| Measurement range | Dry measurement: 20 µm - 20 mm Wet measurement: 5 µm - 3 mm |

| Method of analysis | Dynamic Image Analysis |

| Type of analysis | Dry measurement of free-flowing powders and bulk solids Wet measurement of suspensions and emulsions |

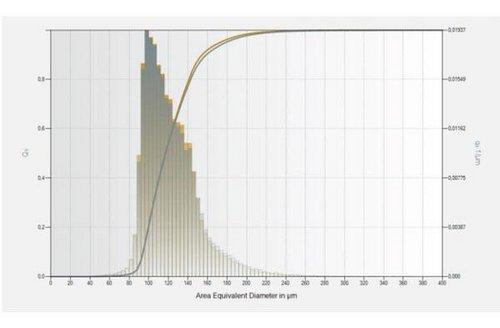

| Measurement values | Particle shape and particle size |

| Standard | ISO 13322-2 |

| Lenses: 3 different, easy to change telecentric lenses | Dry Measurement Enlargement / Measuring range: 1. 0.157x / ~ 90 μm – 20 mm 2. 0.35x / ~ 40 μm – 9 mm 3. 0.735x / ~ 20 μm – 4.5 mm Wet Measurement Enlargement / Measuring range: 1. 0.35x / ~ 20 μm – 3 mm 2. 0.735x / ~ 10 μm – 2 mm 3. 1.333x / ~ 5 μm – 1 mm |

| Size of the Measuring Field (FoV) / Depth of Field (DoF) | Dry Measurement: 3 lenses FoV / DoF 1. 53.8 x 45 mm / ~ 27 mm 2. 24.1 x 20.2 mm / ~ 5 mm 3. 11.5 x 9.62 mm / ~ 1.2 mm Wet Measurement: 3 lenses FoV / DoF 1. 24.1 x 20.2 mm / ~ 5 mm 2. 11.5 x 9.62 mm / ~ 1.2 mm 3. 6.34 x 5.3 mm / ~ 0.5 mm |

| Camera | 5 megapixel CMOS camera 2,448 x 2,050 pixel resolution USB 3.0 |

| Typical measuring time | < 5 min (depending on the desired measuring statistics) |

| Typical sample quantity | Dry Measurement: 10 - 100 g Wet Measurement: 0.1 - 1 g |

| Measuring speed | max. 75 images/s |

| Evaluation | Fast image analysis for morphology description and particle size determination |

| Software | ImageSizing-Software ISS for controlling, recording and evaluating the measuring results pre-installed on supplied computer, including monitor, keyboard and mouse (without computer hardware for deliveries to CIS countries) |

| System requirements (for computers supplied by customer) | Standard Windows PC with Intel Core i7 Quad Core processor or better, at least 16 GB main memory, drives: 1 TB SSD, 1 TB HDD, USB 3.0 port, Windows 10 (64 bit), monitor with 1,920 x 1,080 pixel or better, keyboard, mouse |

| Dimensions (W x D x H) | Dry Measurement: 90 x 30 x 55 cm Wet Measurement: 90 x 30 x 55 cm and 29 x 27.2 x 29 cm (wet dispersion unit) |

| Net weight | Dry Measurement: 36.8 kg Wet Measurement: 58.8 kg |

Meets the requirements of ISO 13322-2 for Dynamic Image Analysis.