Battery Testing Overview

Turnkey automotive battery testing solutions for research, development and validation

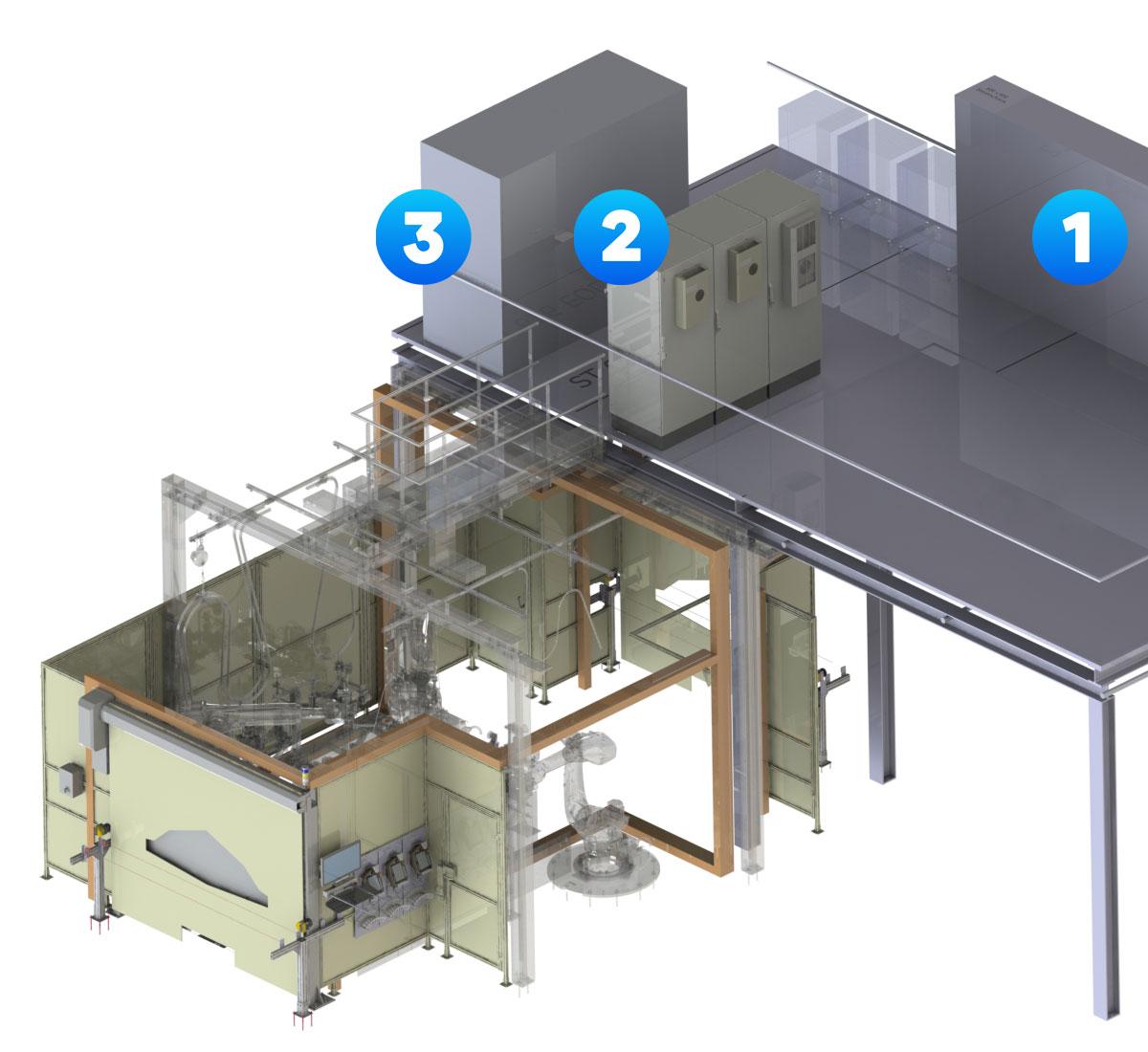

Addressing the advanced needs of modern battery production processes, HORIBA offers the Evaluator End-of-Line (EOL) system series. This series caters to a wide spectrum of applications, from prototype or low-volume production lines to fully automated giga factories.

The Evaluator series focuses not only on test equipment, but on the complete station design includingsafety, test item adaptation, housing, data handling, and seamless communication with other systems. The cost-effective design can include conveyer belts with semi-automated or fully automated product-specific battery bonding. Optional industrial PC or operator panel integration enhances usability, while streamlined production software simplifies procedure management, ensuring seamless start and stop functionalities.

Additionally, the EOL system facilitates automated display of pass/fail criteria and read/write access to customer production databases. With fail-safe PLC control mechanisms, the system ensures safety without compromising performance.

HORIBA End-of-Line Battery Testing Stations:

► Contact us now for individual consultation and a customized offer!

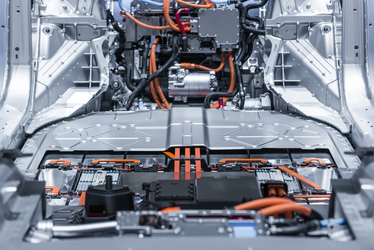

High-Voltage (HV) Battery Testing scheme:

The X-HVT charge-discharge units provide excellent accuracy at high-system dynamics. A single unit covers voltages up to 1,500 V, currents up to 1,500 A, and outputs up to 1,000 kW. Parallel alignment enables higher currents and power.

Fully programmable control circuits (CC, CV, CP) allow optimal adaption to the inspection needs, including map control. The system’s advanced technology enables optimized energy recovery. For multi-channel configurations, the energy can be distributed in an intermediate circuit, thus reducing power input required.

Especially with End-of-Line (EOL) applications and test fields, this property displays as particularly advantageous. An integrated sequencer (program memory) allows the generation of highly dynamic loading cycles and user-specific tests. The optional integrated impedance measurement (CCMod) is an indispensable tool for the continuous investigation of electrochemical phenomena and efficient diagnostic strategies.

► Contact us now for individual consultation and a customized offer!

End-of-Line Battery Testing Systems

Safety Cabin

Adaption

Test Item Transportation

Chiller

Safety Features

Input Parameter Test

BMS Test

Open Circuit Voltage

Insulation Test

Performance Test

Dielectric Strength

Energy Recovery

Cascadability

Range

Accuracy

Data Logging

Scanner

CAN Gateway

Connectivity

Cooler Leakage and Blockage

Housing

Operator Panel

Client PC

Charge-Discharge Unit for High Voltage Emulation

Power Rating

Overall Efficiency at Power Rating

Noise

Operating Modes

Voltage Range

Current Range

Measurement Accuracy

Resolution

Sampling Rate

Storage Rate

Cycle Time

Standard Models

Setpoint

Parameter

Frequency Range

Impedance Range

Impedance Accuracy

Phase Angle Accuracy

Max. Modulation Current

Ripple

Risk Assessment

Safety Controllers

ISO Controller

Safety Version according to ISO 13849 / EN 60204-1

Verification of the functional safety (audit trail) incl. creation of validation certificate ISO 13849

Sie haben Fragen oder Wünsche? Nutzen Sie dieses Formular, um mit unseren Spezialisten in Kontakt zu treten.