Please tell us a bit about DNW and what you do.

DNW is one of the most specialized organizations in Europe for high-quality and innovative wind tunnel testing for the aerospace and automotive industries. We operate seven wind tunnels including subsonic, transonic and supersonic facilities and offer experimental aerodynamic simulation options.

We are a non-profit foundation under Dutch law, with headquarters in Marknesse in the Netherlands. Our tunnels are situated in several locations in the Netherlands and Germany: Marknesse, Amsterdam, Braunschweig, and Göttingen

How did you come up with the idea for a dedicated Automotive Test Section?

The introduction of the WLTP※ created a need for highly accurate measurement of aerodynamic drag and other driving resistances in larger vehicles, such as SUVs, vans, and light trucks. However, relying solely on computer simulations to determine the drag coefficient is insufficient, as these models can only approximate real-world conditions. Factors such as body panel gaps, seals, and tires are difficult to accurately represent in simulations. Further, production tolerances of vehicles are not represented in simulation models.

To achieve the necessary precision, drag coefficients must therefore be measured in a wind tunnel. However, most existing wind tunnels and their measurement systems were designed for traditional passenger cars and SUVs, making them inadequate for testing larger vehicles like vans and light commercial vehicles (LCVs). Many OEMs lack wind tunnels with the required dimensions to accommodate these larger models

Why did you reach out to HORIBA?

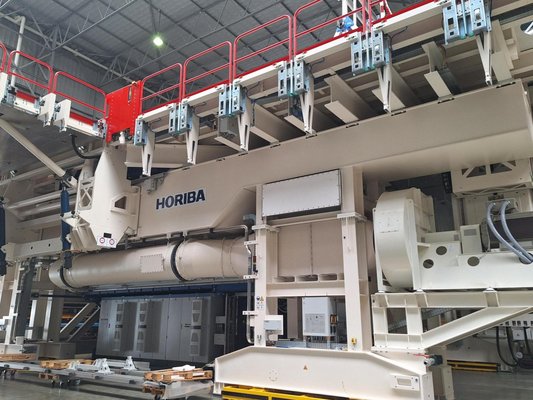

Wind tunnel balances and road simulation systems are a very unique business. And not many suppliers have the knowledge and capabilities in this area. HORIBA has been a valuable partner for us in the past. And with their extensive background in this business and the number of systems they have delivered worldwide, we were quite confident that they would be able to develop a custom solution that meets the needs of this specific project.