Model | ENDA-5000 | ||||||

Component | NOX | SO2 | CO | CO2 | O2*1 | ||

Measurement methods | NDIR | NDIR | NDIR | NDIR | Magneto-pneumatic detection | ||

Range*2 | Standard | 200~5000 ppm | 200~5000 ppm | 200~5000 ppm | 5~25 vol% | 10~25 vol% | |

| Optional | 100 ppm~ | 50 ppm~ | 100 ppm~ | - | - | |

Range Ratio | Within a factor of 10 | Within a factor of 10 | Within a factor of 10 | Within a factor of 5 | Within a factor of 2.5 | ||

Repeatability | Within 0.5% of full scale (with optional range, or during O2 measurement, ±1.0% of full scale) | ||||||

Linearity (indicator error) | ±1.0% of full scale | ||||||

Zero drift | ±1.0% of full scale (assuming surrounding temperature is maintained within 5 °C) | ||||||

Span drift | ±2.0% of full scale/week (assuming surrounding temperature is maintained within 5°) | ||||||

Response time*3 | Within 60 seconds (Td + T90 from equipment intake area) (sample flow 0.6 L/min.) (within 240 seconds for SO2 only) | ||||||

Overall interference frrom co-existing gases | ±2.0% of full scale/week (within standard range, with standard gas formation) | ||||||

Display | Touch panel LCD (backlight) (four usable lines) | ||||||

Environment | Temperature | -5 to 40 °C (away from direct sunlight and radiation heat )*4 | |||||

Humidity | 85% or less (no condensation) | ||||||

Vibration | 100 Hz, 0.3 m/S2 or less | ||||||

Dust | Standard environment or better | ||||||

Measuring Gas Condition | Temperature | 250 °C or lower | |||||

Dust | 0.1 g/Nm3 or less | ||||||

Standard gas composition*5 | NO: 500 ppm or less; NO2: 15 ppm or less; SO2: 1000 ppm or less; SO3: 50 ppm or less; | ||||||

Sampling method | Dry sampling using an electric cooler | ||||||

Sample gas flow | 2.5 L/min~3.0 L/min | ||||||

Sample inlet tube | Teflon tubing (Ø8/Ø6 mm) | ||||||

Sample gas pressure | ±4.9 kPa (three points selected) |

| |||||

Pressure control | Pressure control uses a regulator and cylinder; Reduced pressure sampling; Control pressure: -4.9 kPa | ||||||

Output | DC 4 to 20 mA (absolute output) (DC 0 to 16 mA/DC 0 to 1 V/DC 1 to 5V optional) Max. 12 output systems | ||||||

External output | Analysis alerts, analysis warnings, range display, corrections, conservation, purging (option) | ||||||

Correction method | Dry correction, automatic correction (correction cycle: 7 days standard, can be adjusted to between 1 and 99 days), manual correction | ||||||

Calibration gas | Zero gas | With measurement method authorization: N2, When there is no measurement method authorization: N2 or ambient air | |||||

O2 carrier gas | Ambient air | ||||||

Span gas | Gas cylinder for each component measured (when there is no measurement method authorization: O2 or ambient air can be used) | ||||||

Probe collection point filter | Flange: JIS 10K, 40 AFF; Sample probe tube length: 1000 mm; Material: SUS-316 stainless steel; | ||||||

Power supply | AC 100 V ±15 V(85 V~115 V) | ||||||

Power frequency | 50/60 Hz (switchable) | ||||||

Power consumption | About 800 VA (heated piping 30m: +1100 VA; heater in tray: +300 VA) | ||||||

Exterior dimensions/Mass | 600 (W) x 1770 (H) x 300 (D) mm (high pressure gas cylinders, 3.4 L cylinders, maximum of 3 cylinders); About 180 kg (not including cylinders) | ||||||

Materials in contract with sample gas | SUS-316 stainless steel, SUS-304 stainless steel, Teflon, polypropylene, polyethylene, | ||||||

Enclosure | Independent outdoor installation | ||||||

Color/Finish | Semi-gloss Munsell 5Y7/1 on all inner and outer surfaces | ||||||

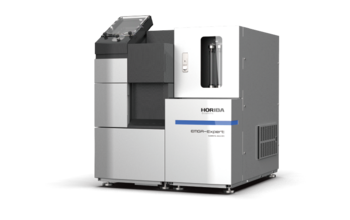

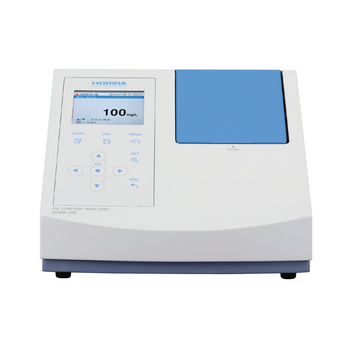

ENDA-5000 Series

굴뚝 배출가스 분석장치

10 만대가 넘는 판매 대수와 30년 이상의 실적을 기반으로 설계된 굴뚝 배출가스 분석 장비인 ENDA-5000S 시리즈는 연속 측정에 탁월한 전처리 장비로, 장기적인 안정성이 보장된 Cross Modulaion방식의 NDIR (NOX, SO2, CO, CO2) 및 MPA(O2)를 적용했습니다. 또한 터치 화면 방식을 채택하여 간단한 설정이 가능하며 유지 보수 작업의 효율을 높였습니다.환경관리공단의 요구에 부합하는 디지털 전송 기능과 함께 연속 감시가 필요한 보일러 배기가스 , 소각장 , 전력 발전소 등 다양한 곳에 적용 가능합니다.

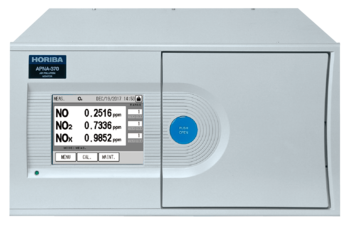

• 5가지 성분 동시 연속 측정

HORIBA의 독자적인 광학계를 통해 5가지 성분을 동시에 측정할 수 있으며 5가지 측정 성분의 자유로운 조합 가능.

• 간섭영향의 대폭 감소

HORIBA의 독자적인 간섭 필터를 통한 간섭 가스의 영향 대폭 감소

• 데이터 디지털 전송

한국환경관리공단의 요구에 부합하는 데이터의 디지털 전송 지원.

• SO2 교정 시간 대폭 단축

기존 장시간(약 15분)이 소요되던 Wet 기준 교정에서 Dry 기준으로 교정법을 채용하여 약 3분으로 단축.