That is an article that was published in Japanese on August 3, 2017.

Introducing a Laser Analyzer Capable of Reducing Annual Maintenance Costs by Half

HORIBA, Ltd. (hereafter HORIBA) is expected to begin receiving orders for the TX-100 Tunable Laser Hydrogen Chloride Analyzer in mid-August. This device allows for laser measurement of hydrogen chloride generated within waste incineration plants and other industrial settings.

Demand for laser analyzers for measurement in waste incineration plants and other locations has been increasing thanks to lower running costs compared with the “wet method” (*1), which employs a conventional electrode and a sample dissolved in water. HORIBA’s laser analyzer incorporates a laser projector and a light-receiving sensor, the first of its kind in Japan, to further reduce maintenance costs.

The hydrogen chloride generated in cleaning factories, cement/petrochemical plants, and other industrial sites results in a strong irritating odor. This exhaust gas also affects the human body, making it a central environmental problem for emerging countries. HORIBA is dedicated to solving such problems through measurement and analysis technology in an effort to establish a viable environmental conservation system.

Wet method (*1): The sample is dissolved in water and measured using an ion electrode.

Development Background

Construction and establishment of plants in the waste incineration market is progressing rapidly in emerging countries. Nevertheless, the issue of exhaust gases generated at waste incineration plants is still a concern. Because waste is made up of various substances, incineration generates not only dioxins but also other acidic gases such as sulfur oxide (SOx), nitrogen oxide (NOx), and hydrogen chloride (HCl). Hydrogen chloride in particular is generated not only from PVC products in waste but also from food waste and paper from kitchens. The technology behind removing acid gases is continuously progressing. As a result, products are currently expected to offer high performance and simple introduction in existing plants.

It is under such conditions that HORIBA developed the TX-100, a tunable laser hydrogen chloride analyzer based on the concept of a product that could be easily installed and easily introduced with reduced running costs compared with conventional models.

In addition, by combining the TX-100 with HORIBA’s Stack Gas Analyzer (*2)—which enjoys a 50% share of the Japanese market—users can not only measure all exhaust gas components (seven components: HCl, H2O + NOX, SO2, CO, CO2, and O2) but also manage all measurement data at once.

Looking forward, HORIBA aims to expand its business in the waste incineration market in emerging countries by making full use of the extensive know-how and experience cultivated throughout the company’s history.

Stack Gas Analyzer (*2): Measurement device placed in the duct that leads burned gas to the stack

TX-100 Features / Comparison with Conventional Methods

- Reduced Running Costs

Compared with the wet method, laser analysis can reduce running costs to about 1/10 per year. Costs arise with the wet method due to periodic exchanges of electrodes and of water for dissolution. Laser analysis on the other hand does not require periodic component replacement, so laser analyzers are becoming more mainstream.

- Simple Installation

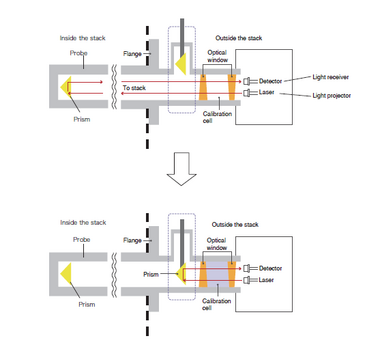

By adopting Japan’s first probe-type optical system (*3), installation of the TX-100 is simple and can be performed from one side of the stack as the light projector and light receiver are on the same side. This makes it possible to adopt the TX-100 even in plants employing the cross-stack method (*4)—where the light projector and light receiver are positioned on opposite sides—simply by replacing only one side (projector side).

Probe method (*3): Method in which the light projector and the light receiver are installed on the same side, and the laser light passes through the probe for measurement.

Cross-stack method (*4): Method requiring a light projector and a light receiver to be installed in two places on opposite sides of the stack. - Reduced Maintenance Costs

With conventional products, calibration required the device to be removed from the stack. HORIBA’s patented technology, however, allows calibration to be performed while the device is installed. This means annual maintenance costs can be cut by half.

(Patented in USA, patent pending in Japan, Europe, and China)

Main Specifications

| Name | Tunable Laser Gas Analyzer |

| Model | TX-100 |

| External dimensions/Weight | Analyzer 358(W)×517(D)×453(H) mm / 19kg |

| Probe | Φ89mm/ 20kg |

| Measurement target | HCl、H2O |

For more information

Products information: Tunable Laser Hydrogen Chloride Analyzer TX-100