Functional Safety

“The absence of unreasonable risk due to hazards caused by malfunctioning behavior of Electronic / Electrical systems.”

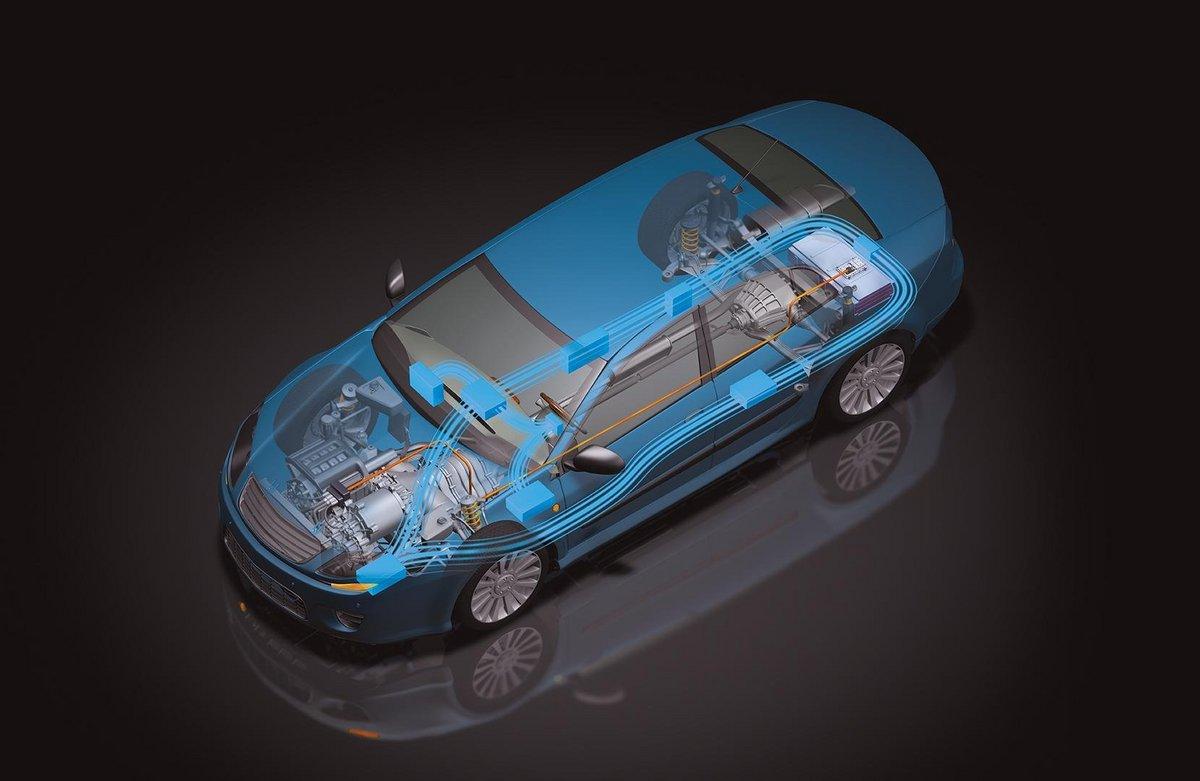

We use proactive engineering to reduce the risks associated with functional safety; using recognized best practices and state-of-the-art standards to help the world’s leading vehicle manufacturers and suppliers develop safer products.

We work at the forefront of both functional safety and SOTIF, actively contributing to the development of the corresponding international standards (ISO 26262 and ISO 21448 respectively) as well as leading internal and external research projects in these areas.

We use appropriate methods based on strong systems engineering principles, extending beyond the scope of the standards where necessary to add value to the performance and capability of our customers’ products, processes, and people.

Click below to jump to the topic of interest:

Verification and Validation

With increased complexity and authority of safety-related systems in today’s vehicles, additional development time and expense have become common. This complicates an organization’s ability to maintain efficiency and deliver programs on time.

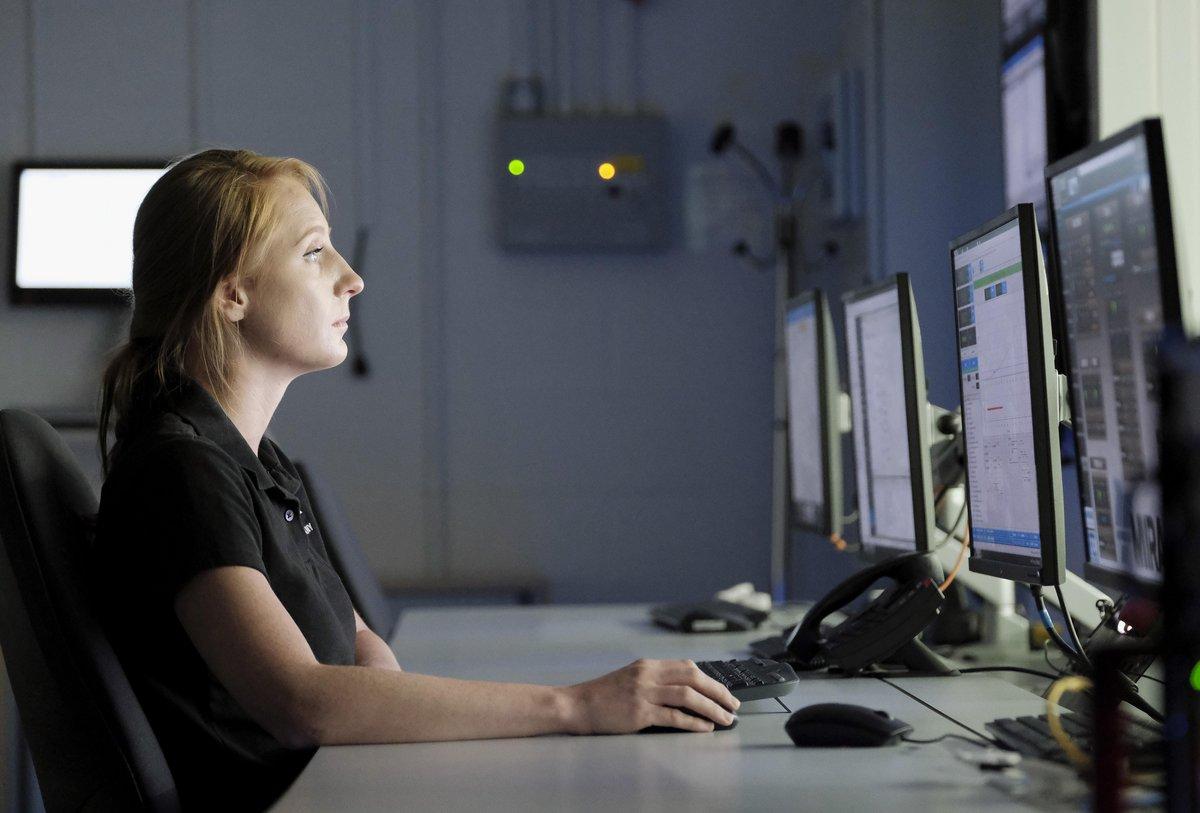

Our Functional Safety Team and SOTIF (Safety of the intended functionality) Verification and Validation Team help OEMs and tiered suppliers meet safety-focused integration, testing, and validation needs. Services range from unit testing to component testing (bring-up and hardware-in-the-loop HiL), vehicle level integration, test services, and vehicle validation programs.

The team can plan, execute, and evaluate results around testing of safety-related systems. Practical expertise covers SiL, PiL, and HiL at lower levels, up to chassis dynamometer and proving ground-based facilities at higher levels. We provide functional safety experts with direct access to all facilities and expertise in all areas of verification and testing.

Testing, integration, and validation services include:

Audit and Assessment

We perform the necessary independent process audits and product assessment activities necessary for ISO 2622 and other standards.

Our engineers, consultants, auditors, and assessors have first-hand knowledge developing safety-related automotive products from concept to design, through to production and deployment. The approach is pragmatic, practical, and solution-focused within a structure that is independent and impartial.

Confirmation reviews, audits and assessments typically align with key program gateways, supporting engineering approvals, and program progression.

Audit and assessment services include:

Engineering Consultancy

Specialized engineering expertise is necessary to address system safety challenges in today’s complex vehicles, but this level of expertise is not always available in-house.

When OEMs and automotive suppliers look to outsource their functional safety workload, they look to our Engineering Consultancy Team. Safety specialists, safety-related skill sets, or capability gaps can be filled on either a short or long-term basis. The team works seamlessly within customer processes, coordinating with existing internal teams and suppliers to accomplish tasks efficiently and deliver projects on time and on budget.

Alternatively, our team can work remotely to deliver defined packages of work aligned to phases or collections of work products from ISO 26262 or other standards.

Engineering consultancy services include:

Process Review and Improvement

Developing reliable, robust, and functionally safe products requires engineering processes that are logical, structured, comprehensive, and repeatable.

We help companies develop their functional safety-related processes and templates according to best practices. Support for integrating results into organization-specific product development processes, and rolling them out to the larger team, is also available. These services help companies achieve and maintain efficiency while keeping the goals of functional safety and cybersecurity satisfied.

With decades of experience in process review and improvement, and significant experience in all automotive domains, we help companies develop products in efficient and effective ways. Our team is comprised largely of former OEM, Tier-1, and Tier-2 employees. This group of professionals provide - practical experience moving products safely to market.

Our team also has direct involvement in the development of ISO standards such as ISO 26262 (functional safety), ISO 21448 (SOTIF), ISO/SAE 21434 (cyber security), and others, as well as involvement in development of the MISRA guidelines so have an unparalleled depth of knowledge.

The Process Review and Improvement approach includes:

Training Courses and Technical Seminars

The development and launch of safe products require defined and repeatable processes implemented by a competent, experienced team. The effective training of the members of this team is an essential element of long-term success.

Our specialized courses include Functional Safety, Safety of the Intended Functionality, and Cyber Security for Automotive Applications. These courses are taught by the same team involved in writing ISO 26262 (Functional Safety), ISO 21448 (SOTIF) and other applicable engineering standards.

Course trainers are also HORIBA Automotive consultants, so the available series of courses is 100% consistent with specialized services.

Training Courses, Technical Seminars, and Webinars include:

HORIBA MIRA, a specialized team within HORIBA Automotive, provides pioneering engineering, research and test services with 75 years of experience developing some of the world’s most iconic vehicles.

Do you have any questions or requests? Use this form to contact our specialists.