by Hideo Ueda and Michael Pohl

(As published in HORIBA Readout, July 2020. Readout is a journal highlighting HORIBA technology that has been published twice a year since 1990.)

The regulations for sulfur concentration in the automotive fuels have now started going down to 10 mg/kg around the world. In the refineries, it is necessary to control the costs for de-sulfurizing the incoming crude oil. In order to do this, it is required to know the incoming sulfur concentration as well as the clean crude oil being distilled in the refinery. The logical technology to employ is Energy Dispersive X-ray Fluorescence (EDXRF) spectrometry as it can easily measure the mass % levels of sulfur in crude oil as well as the ppm (mg/kg) levels of sulfur in the final product. The HORIBA MESA-7220V2 has been developed in order to meet these two concentration ranges and everything in between.

Introduction

Sulfur is naturally occurring in all crude oil samples and thus appears in refined fuel samples. The pollution effect of the sulfur combustion products as well as the poisoning of catalytic systems make continued reduction in sulfur concentrations essential. The current level in Tier 3 gasoline is set at the 10 mg/kg level and is expected to be reduced in the future.

In the case of diesel fuel, the limit for low sulfur diesel was set at 500 mg/kg in the mid 1990’s and ultra-low sulfur diesel at 15 mg/kg in 2006. These regulations were originally specified for on-road vehicles; but have now been expanded to include construction equipment, trains, and home heating oil. There is even a movement afoot to extend it to the maritime industry in the future. These sorts of requirements were exactly the ones which were used in the MESA-7220 design.

If the requirement is restricted to the sulfur in crude oil, then ASTM D4294 is an excellent, cost effective solution. With a measurement range of 17 mg/kg to 4.6 mass %, the requirements for crude oil are easily met. In order to meet these needs over the years, HORIBA has developed the SLFA-60, SLFA-6100, and the SLFA-6800.[1] These units measure samples inside enforcement vans, on board ships and in independent test labs.

As the sulfur concentrations in fuels have gone lower and lower, the D4294 technology did not have the required sensitivity. As a result, some modifications to the basic design were required. The approach taken was to reduce the noise level so that the small sulfur peak could be more easily detected and quantified. This was accomplished with the use of special optics to filter out the undesirable X-rays from the detector. The result of this work was the MESA-7220 and ASTM Method D7220.

ASTM D7220-12

The new revision of the method D7220 was approved in 2012 just in time for use with some of the newer fuel requirements. The method is written around a series of petroleum types. These include gasoline, home heating oil, jetfuel, and others. The scope of the method is 3 mg/kg up to 942 mg/kg. The method is based upon the EDXRF method. This method is based upon a number of new optical developments. As a part of the method, the source of the X-ray was specified to be an end window X-ray tube with Ag or Pd electrode. This beam then hits a Highly Oriented Pyrolytic Graphite (HOPG) crystal which works as an X-ray diffraction grating. This Bragg Optic is designed to produce mono-chromatic Ag or Pd radiation which is focused on the typical sample cell containing the material of interest.

The resulting X-rays coming off the sample, primarily sulfur fluoresced X-rays then get into the detector. The X-ray detector is typically a Silicon Drift Detector (SDD), but it must have a resolution value not to exceed 175 eV at 5.9 keV and 10 kcps. Using a detector meeting these requirements has proven essential to separate the fluorescence peak of chlorine from that of the sulfur. These elements both appear in petroleum type samples and this separation is required to avoid chlorine from interfering with the sulfur measurement.

In order to avoid the effect of low levels of Ar present in atmospheric air, a vacuum of ≤ 4.0 kPa must be applied to the X-ray optical system. In addition, the instrument must include signal conditioning and data handling electronics. These features permit the X-ray intensity counting and spectral analysis. It also allows for the subtraction of background X-rays, peak deconvolution, and calculation of overlap corrections. This results in the conversion of X-ray intensity into sulfur concentration.

X-ray Optics and Performance

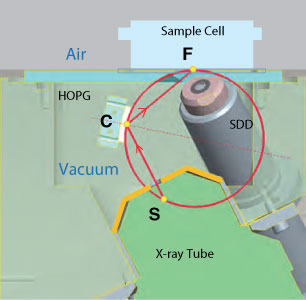

The MESA-7220V2 has been developed as a mono-chromatic EDXRF instrument. It is equipped with an end window X-ray tube with an Ag anode. The X-ray is diffracted on a HOPG crystal which passes the Ag-Lα radiation. This radiation strikes the sample cup and the emitted X-rays are directed into an SDD.

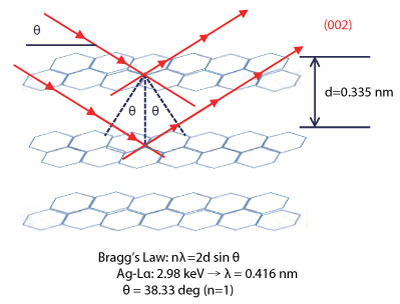

The HOPG crystal [2] is prepared in a high temperature furnace also under high pressure. Layers of poly-imide film are laid down, and the heat and pressure is applied. The resulting graphite block is composed of highly oriented carbon layers. This material acts as a diffraction grating to be used as a monochromator for Ag-Lα X-rays of 2.98 ± 0.02 keV as illustrated in Figure 1. This is then configured as a slightly curved crystal.

Figure 1: HOPG

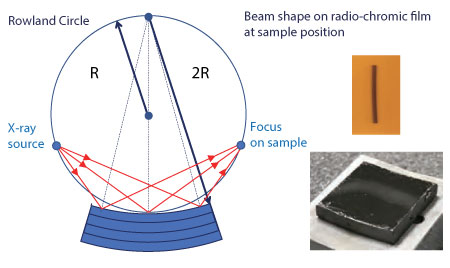

This curvature is required in order to make the X-ray beam converge. A singly curved HOPG crystal whose radius of curvature is equal to 2R creates a converging optic called a Rowland circle. This circle whose radius is equal to R is illustrated in Figure 2. The X-ray source, the center of the HOPG surface and the focal point on the sample all fall on the circumference of the Rowland circle.[3] The result of the X-ray focusing of the beam prior to the sample cell is a line shaped beam.

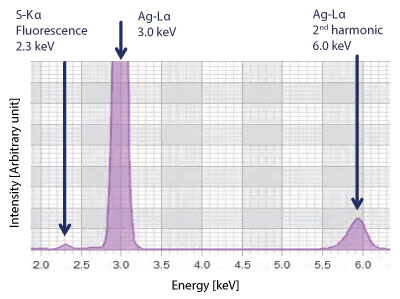

The complete MESA-7220V2 optical system is shown in Figure 3. The X-ray beam from the Ag anode, the center of the HOPG surface, and bottom of the sample cell are all aligned on the circumference of the Rowland circle. The HOPG crystal can then be manually rotated to find the best angle to maximize the S-Kα intensity. An example of the spectrum which is produced is shown in Figure 4. The Ag-Lα and its second harmonic are diffracted from the HOPG crystal. The former is the characteristic X-ray anode of the X-ray tube and the latter is the continuous X-ray from the target.

Figure 2: Singly curved HOPG

Figure 3: X-ray optics

Figure 4: X-ray spectrum

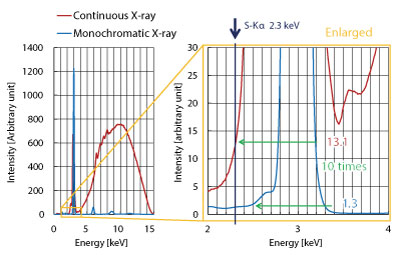

The optics are receiving both the fluoresced X-ray and the scattered X-ray from the sample. Comparison of the spectra caused by continuous X-ray excitation versus monochromatic excitation is shown in Figure 5. Measurement of blank (sulfur-free) sample shows up the background of the sulfur measurement. It illustrates the 10 fold improvement of S-Kα intensity for blank mineral oil with the monochromatic beam. The data analysis yields a Limit of Detection (LOD) of 3.2 mg/kg for the continuous X-ray beam and 0.5 mg/kg for the monochromatic beam. Thus the much better sensitivity of the mono-chromatic instrument is proved.

Figure 5: Lower back ground

Figure 6: MESA-7220V2 and the optional 8 positions turntable

Features and Benefits

(1) Auto-Sampler

The turntable is an option which can automatically switch samples to speed up the analysis and reduce the operator involvement. The 8 position sampler is shown in Figure 6.

(2) Measurement Modes

The software offers four different modes of analysis. These include sulfur-only analysis, chlorine-only analysis, sulfur/chlorine analysis and sulfur analysis including oxygen correction.

(3) Auto Ranging

Normal operation includes the use of three different calibration curves. These are for low, middle and high concentrations for most accurate determinations based upon the intensity of the S-Kα X-rays. These calibrations can be combined to form a single curve to simplify operation.

(4) Replacement of the vacuum window

The mono-chromatic X-ray beam exits through the Kapton® Window to hit the sample cell. This window can easily be replaced by a normal operator. Replacement windows are provided to the user as a part of the ship kit.

Instrument Applications

(1) Sulfur in petroleum products

With an LOD lower than 1 mg/kg, this instrument is useful for all standard fuel samples. Since the instrument has been shown to be compliant with ASTM D4294, it can also be used for high sulfur samples such as crude oil and residual oil.

(2) Sulfur in Biofuels

Due to addition of an oxygen correction factor ethanol, biodiesel, reformulated gasoline and biodiesel blends can be analyzed. These oxygen correction factors are derived from the measurement of the scattered X-ray from oxygen. This all happens automatically with no intervention by the operator.

(3) Chlorine in petroleum products

The fluorescence for the Cl-Kα peak is closer to the excitation energy of the Ag-Lα than is S-Kα. Thus the chlorine produces a stronger peak and so provides good sensitivity. The LOD for the chlorine is thus less than 0.6 mg/kg. The biggest challenge is that in many cases the chlorine appears in a sample which has very high sulfur concentrations. With proper peak separation of the sulfur and chlorine the chlorine can be accurately measured. A good example is ASTM method D4929.

Conclusion

The MESA-7220V2 complies with a series of ASTM methods. From D7220 to D4294 plus D4929, this instrument has proven to be very useful. The application will only continue to grow in the future.

* Editorial note: This content is based on HORIBA’s investigation at the year of issue unless otherwise stated.

References

[ 1 ] Sumito Ohzawa: “Sulfur in Oil Analyzer SLFA-60”, p.109, Readout (HORIBA Technical Report), 42 (2014).

[ 2 ] Cynthia G. Zoski: “5.2.1 Highly oriented pyrolytic graphite”, p.115, Handbook of Electrochemistry (2007).

[ 3 ] Jeroen A. Van Bokhoven, Carlo Lamberti: “6.6.2 X-ray emission spectrometers”, p.141, X-Ray Absorption and X-Ray Emission Spectroscopy: Theory and Applications (2016).

Authors

Hideo Ueda

Scientific & Semiconductor Instruments R&D Dept.

Research & Development Division

HORIBA, Ltd.

Michael Pohl, Ph.D.

Vice President

HORIBA Instruments, Inc.