For many nanoparticle or submicron particle size samples, both laser diffraction and dynamic are viable analysis techniques. Sometimes, there is a clear reason to choose one or the other. HORIBA offers both the LA-960V2 Laser Diffraction Particle Size Analyzer and the SZ-100V2 Dynamic Light Scattering Analyzer for nanoparticle (submicron) particle characterization. Therefore, the question of which to choose is common.

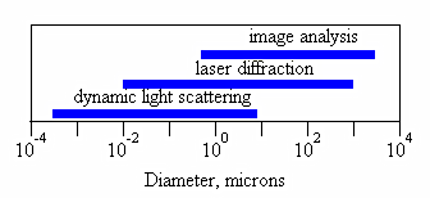

First, let us briefly review the techniques. In dynamic light scattering, particle motion is determined from measured fluctuations in the intensity of scattered light. Particle motion is interpreted as free diffusion and converted to size. For these measurements, particle motion is important to the results. In laser diffraction, particle size is determined from the measured variation in the intensity of scattered light as a function of scattering angle. Particle motion is less important since scattered intensity vs. angle is a direct function of particle size. Both techniques analyze the data using the assumption that the particle is a perfect sphere. And, as shown in Figure 1 below, the size range over which each instrument is useful overlaps significantly.

Figure 1: Size ranges of common particle analysis techniques. Note the overlapping ranges.

The primary consideration when choosing an analyzer should be the practical results of running the relevant sample and, ideally, results from measurement with each technique should be compared. Important secondary considerations include sample volume, other samples, other features, ease of sample preparation, speed, and nature of expected impurities. Thus, a critical first step is to identify the most important materials that should be analyzed and secure some test samples. These samples can then be run on each analyzer and the results compared for ease of measurement, reproducibility, and accuracy. Note that for nearly every material, laser diffraction and dynamic light scattering will give somewhat (often 10~20%) different results.

Sample volume is important when analyzing precious samples where little material is available for analysis. Dynamic light scattering measurements can be made on microliters of sample suspension while the minimum volume for laser diffraction is measured in milliliters. With both systems, sample suspension can be recovered after measurement. If the sample is highly concentrated and requires dilution before measurement, the larger sample volume of laser diffraction is advantageous.

Another common decision point involves sample concentration, i.e. particle loading. Dynamic light scattering is typically more suitable for sample systems which generate very weak scattering. Scattering is informed by particle size, chemical and structural nature, and the concentration of particles within the measurement volume. A decent rule of thumb is that if the sample concentration is described in mg/mL, then DLS is the better starting point.

The nature of other expected samples will also affect instrument choice. The lower limit for particle size determination by dynamic light scattering is much lower than that of laser diffraction. Conversely, the upper limit of particle size determination by laser diffraction is much higher than that of dynamic light scattering. Therefore, if other samples are expected to be significantly smaller than the primary sample, dynamic light scattering is often the better choice. However, if the other samples are expected to be significantly larger, laser diffraction is often the better choice.

Other instrument features can also affect one’s choice of an analyzer. Dynamic light scattering systems such as the SZ-100 frequently include the option to measure zeta potential, a predictor of suspension stability in electrostatically stabilized systems. If this option is important, then it is a consideration when selecting an analyzer. Laser diffraction instruments are capable of directly measuring powders, pastes, creams, and gels -- functionality which is not available from the DLS technique.

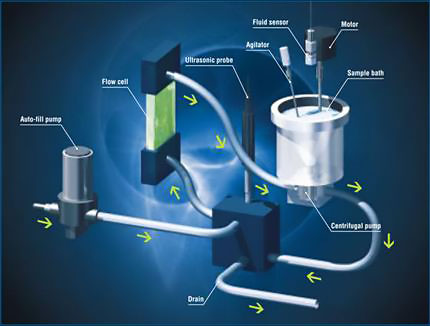

Measurement speed and convenience is another consideration. Both techniques are very fast (on the order of minutes) and laser diffraction measurements can be faster than DLS measurements. However, and more importantly, laser diffraction features such as autofill, auto rinse, and ultrasound can make measurements faster. Dynamic light scattering measurements can be done with disposable sample cells. In both cases, the details of throughput will depend on the sample.

Figure 2: Automated ultrasound, dilution, and cleaning shown in this laser diffraction system can make a lab more productive.

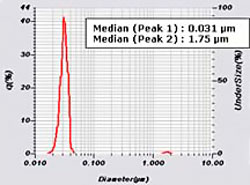

A final consideration is the nature of expected impurities. And this requires some comments about the limits of each measurement. Dynamic light scattering can be used with samples that have much smaller particle sizes than laser diffraction. Therefore, a significant fraction of very small particles will be observed by dynamic light scattering more readily than by laser diffraction. Laser diffraction can be used to analyze samples that have large particles. This is due to the physics of the measurements and the practical ability to pump a sample to ensure that large particles do not settle out of the measurement area which can happen in DLS. Due to this pumping or stirring action, laser diffraction is a better choice for analyzing samples that may contain large particle impurities that need to be sensed.

Figure 3: Laser diffraction analysis of a CMP slurry shows small quantity of micron size impurities that are important to process.

In summary, important secondary considerations include sample volume, other samples or expected future uses, ease of sample preparation, speed, and nature of expected impurities (or problems). Considering secondary conditions will help the user to choose the best analyzer for the job. Often, expected issues with large particle impurities makes laser diffraction a better choice.

Laser Scattering Particle Size Distribution Analyzer

Nanoparticle Analyzer

Laser Scattering Particle Size Distribution Analyzer

Você tem alguma dúvida ou solicitação? Utilize este formulário para entrar em contato com nossos especialistas.