Application 1 : Blank Mask Inspection

PR-PD3 BLI

Enables high-throughput, blank mask particle detection down to 0.1 μm; multiple substrate materials blank mask inspection capability.

Features;

Optimal throughput can be achieved via sensitivity settings.

Application 2 : Patterned Reticle Inspection

PR-PD3 Pro

Detects particles on a wide range of mask and reticle. Enables high throughput with simple operation and 0.5 micron sensitivity.

Microscopes with multiple magnification are built in for particle observation and image data can be stored in the system.Valuable options are available, such as auto focus, auto sizing, etc. and data management functions are also available. Compact equipment design can save the installation space.

Features;

Multi surface inspection

Inspection of 3 surfaces within about 15 minutes*

Pattern surface 0.5 μm

Glass surface 5 μm

Pellicle surface 5 or 10 μm

* Load or Unload included

Sample case handling

SMIF box

Popular stepper case

Application 3 : Advanced Pellicle Inspection

PR-PD3EP

Detects particles on leading edge pellicle membranes enabling high throughput inspection of multiple membrane materials.

Auto defect image capture function

Automatically locates particles, captures images and saves to file

Auto defect sizing function

Automatically calculates size of particles based on captured images

Reticle edge handling

Complies with SEMI standard

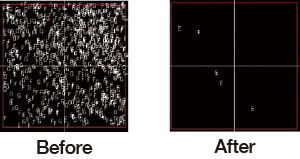

Application 4 : Particle Removal

Automatically removes particles from wafers, reticles and pellicle surfaces with air / N blow and vacuum suction. Prevents the removed particles from re-adhering.

Reduction in running costs

Removal of particles by routine use extends both the replacement cycle of the pellicle and the cleaning cycle of the mask.

When particles on the glass surface are removed (OSL 5.0 μm)