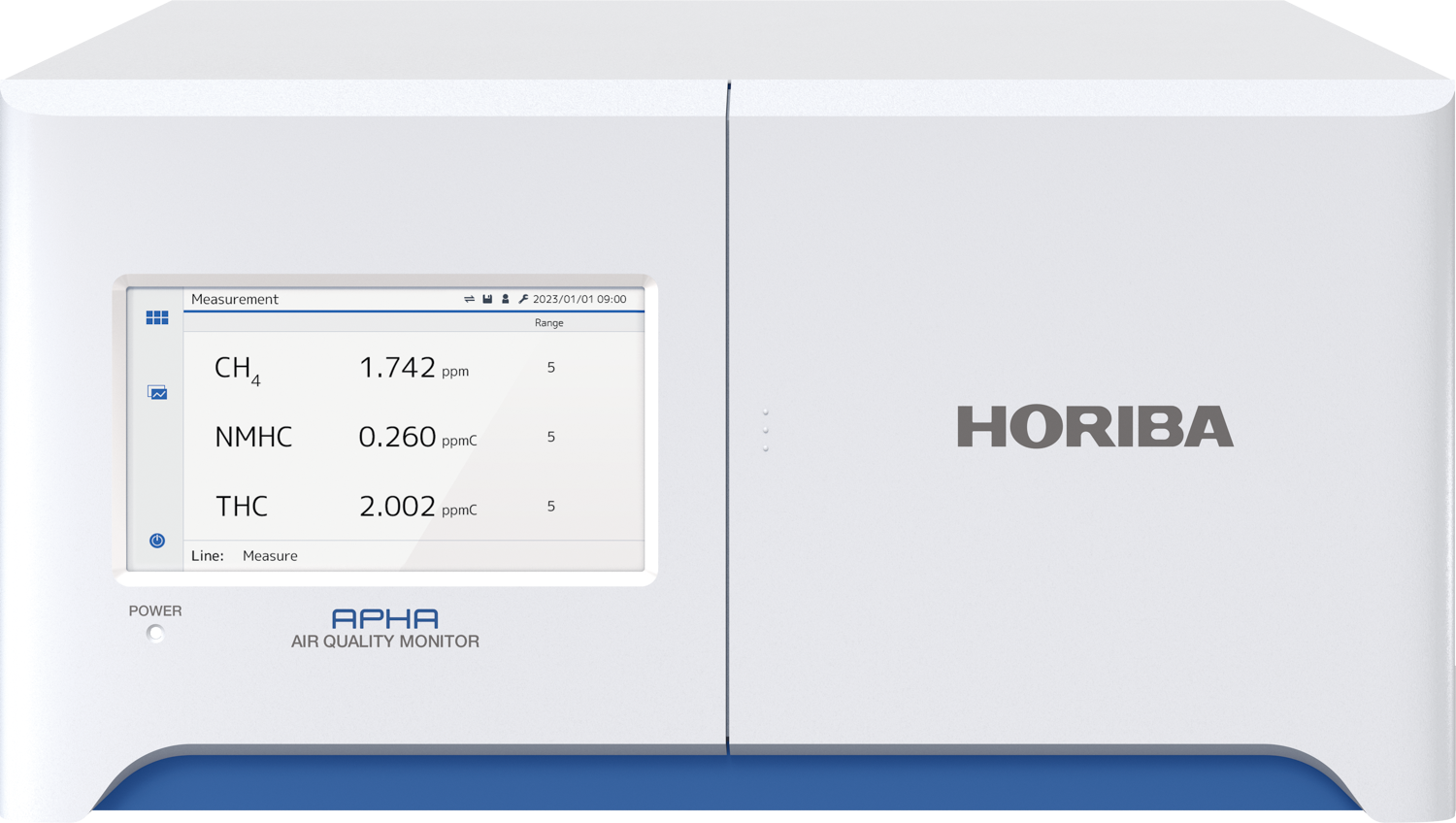

■ APHA-380 Specifications

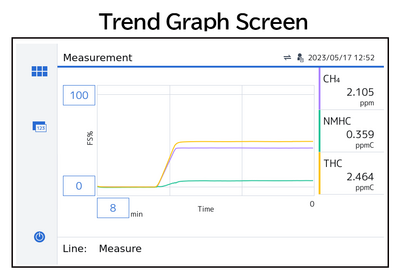

| Component | Methane, non-methane hydrocarbons, total hydrocarbons (CH4, NMHC, THC) |

|---|---|

| Measuring principle | Flame lonization Detector Method (FID) with Selective Combustion |

| Measurement range | 0-5/10/20/50/100 ppmC (up to 5 ranges selectable, auto-range) |

| Lower Detection Limit (2σ) | < 0.02 ppmC*1 |

| Measurement unit | ppmC, ppm |

| Sample gas flow rate | Approx. 0.8 L/min |

| Repeatability | ±1.0% of full scale |

| Linearity | ±1.0% of full scale |

| Zero drift | < 0.025 ppmC (24 h) |

| Span drift | < 0.5% of full scale (24 h) |

| Response time (T95) | < 40 s from the inlet*1 |

| Display | 7-inch color LCD with touch panel |

| Communication | Ethernet × 2 (Modbus® TCP), RS-232C × 1 (Modbus® RTU) , USB flash drive × 1 |

| Analog output (option) | Maximum : 3 channels (insulated) DC4-20 mA, DC 0-0.1 V, DC 0-1 V, DC 0-5 V or DC 0-10 V |

| Digital output (option) | Relay contact output for range 3 channels, relay contact output for other 6 channels |

| Digital input (option) | Maximum : 4 channels, non-isolated input |

| Installation environment | Operation temperature : 0-40℃ (32℉ - 104℉), relative humidity : 85% or less |

| Temperature and pressure compensation | With |

| Sampling pump and filter | Internal |

| Power supply | AC 100-240 V±10% (max. voltage: AC 250 V) 50/60 Hz, consumption 230 W |

| Dimensions, weight | 430 (W) x 568 (D) x 221 (H) mm, Approx. 26 kg |

| Compliance | CE, UKCA, KC, FCC, China RoHS |

*1 : Digital filter

・If there is other measurement range requirement than shown above, please consult HORIBA

・Modbus is a trademark of Schneider Electric USA Inc.

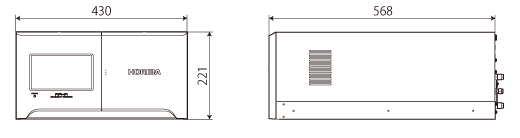

■ Dimensional Outline (Unit: mm)

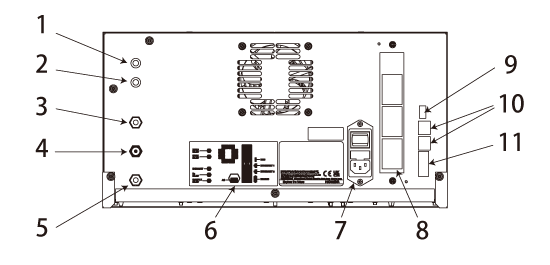

■ Rear Panel Configuration

1. Zero calibration gas inlet (option) 7. AC power connector

2. Span calibration gas inlet(option) 8. I/O terminal block

3. Exhaust 9. USB flash drive connector

4. Fuel (H2) inlet 10. Ethernet connector

5. Sample gas inlet 11. RS-232C connector

6. Guide label

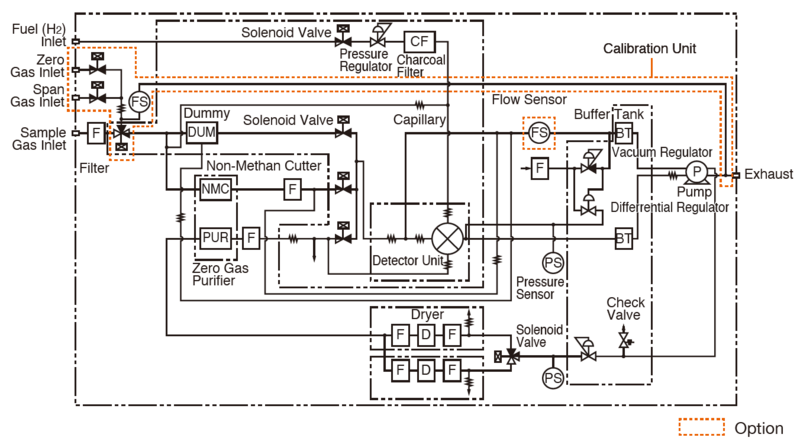

■ Flow Sheet

■ Options

▪ I/O terminal block (Analog input/output, digital input/output)

▪ Pressurized calibration unit ▪ Flow sensor ▪ USB flash drive

▪ Mounting parts (rubber feet, brackets and slide rails, brackets for slide rails)

Ultimate Performance

Ultimate Performance User-Friendly Interface & Functionality

User-Friendly Interface & Functionality

Reduced Operational Expense & Maximum Uptime

Reduced Operational Expense & Maximum Uptime Connected & Intelligent

Connected & Intelligent

Environment-Friendly Design

Environment-Friendly Design Hydrogen-Generator OPGU Series

Hydrogen-Generator OPGU Series