HORIBA supports customers' development and production of fuel cells (FC) with a wide range of technologies from material evaluation to production process and performance evaluation of cells and stacks.

A fuel cell is a device that generates electricity through a chemical reaction between hydrogen (H2) and oxygen (O2). Fuel cells are classified into two types according to their power generation principle and operating temperature: low-temperature fuel cells and high-temperature fuel cells. The low temperature type is called Polymer Electrolyte Fuel Cell (PEFC), and the high temperature type is called Solid Oxide Fuel Cell (SOFC). There are also "mobile" fuel cells installed in Fuel Cell Electric Vehicles (FCV or FCEV) and "stationary" fuel cells installed in homes and factories.

Table of Contents

To improve the performance, reliability, and durability of fuel cells, a wide range of evaluations are required, from electrochemical measurements during power generation, analysis of each component after power generation is completed, to evaluation of the physical properties of each component. In addition, since the characteristics required of fuel cells vary depending on the application, it is necessary to analyze, measure, and evaluate fuel cells under a variety of conditions.

We offer various analytical instruments for research and development of advanced materials. The physical properties of materials such as catalysts, electrolytes and separators for fuel cells can be evaluated using a variety of analytical methods.

HORIBA Solution >>

Applications for Energy

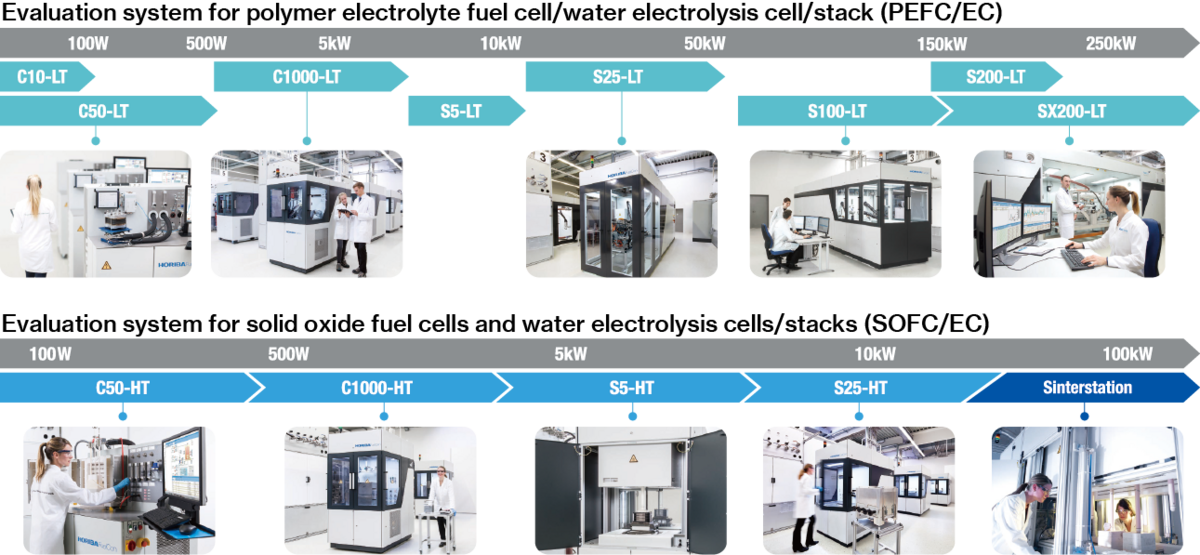

Our fuel cell test stations the Evaluator Series are ideal for testing and evaluating from single cell to full stack and fuel cell systems. In addition to performance evaluation, durability evaluation and accelerated degradation tests are performed based on high safety standards.

Also, Hydrogen Gas Analyzer HyEVO can evaluate fuel cell performance by measuring unreacted hydrogen gas that permeates (cross leaks) through the electrolyte membrane.

HORIBA Solutions >>

PEM Fuel Cell Testing Equipment Evaluator LT Series

Fuel Cell Test Equipment for SOFC Evaluator HT Series

Hydrogen Gas Analyzer HyEVO

Fuel cells generates water during power generation. The pH value (acidity/alkalinity) of this generated water changes due to degradation of the electrolyte membrane and corrosion of the metal separator. By monitoring the pH value of the generated water, the degradation state of the fuel cell materials can be determined.

By measuring the water quality in the exhausted condensate and the CO2 in the exhaust gas, the degree of degradation of the fuel cell also can be evaluated.

HORIBA Solutions >>

Micro Volume pH Monitor UP-100

Ambient Carbon Dioxide (CO2) Monitor APCA-370

In the development of fuel cells, mixed gases under various conditions are simulatively created, and the gas flow is controlled and supplied to the fuel cell for testing and evaluation. This requires high-precision vaporization, mixing, and flow control equipment. HORIBA has flow control technology, which is also used in semiconductor processes, and supports fuel cell development and testing with accurate control of gas concentration and humidity. For more information, please click here.

HORIBA Solutions >>

For controlling H2/O2/ N2 gas flow precisely: Digital Mass Flow Controller SEC-N100

For controlling and monitoring the pressure in the line: Auto Pressure Regulator UR-Z700

For measuring H2O for humidification control: Liquid Mass Flow Meter LF-F20

For monitoring line pressure: Capacitance Manometer (pressure sensor) VG-200S (Please contact us with details.)

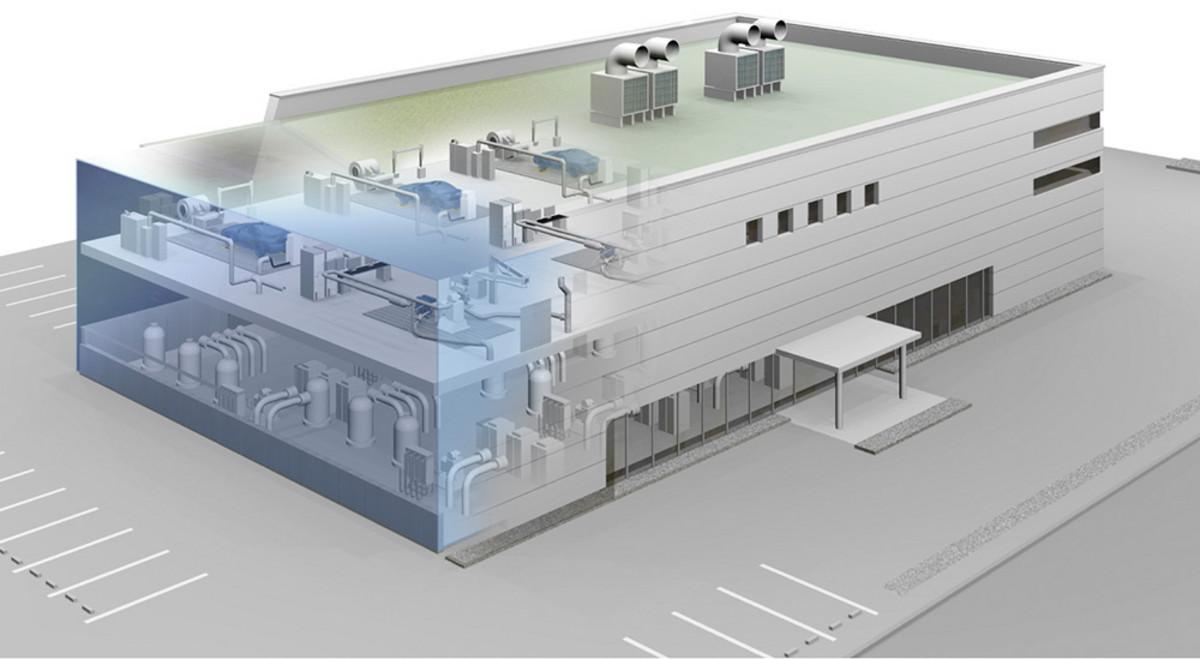

When launching a test building to handle hydrogen, more stringent safety measures are required than before.

Our turnkey solution, a total laboratory construction package, includes ordering multiple contractors, meetings to determine specifications, safety, process and quality control of construction, as well as post-introduction operation, maintenance, and work efficiency, all with an emphasis on safety and ease of use until just before the start of laboratory operations. We can handle the entire construction process on behalf of our busy customers.

We have a long-standing commitment to analysis and evaluation of advanced materials. Your sample is measured by a highly-trained member of our Application Centers and presented as a formal report complete with method, observations, results and data interpretation assistance.

In addition to consultation on the selection of analytical instruments, we also provide analytical technologies through services such as contract analysis and joint research with customers and academia, utilizing our know-how and skills as an analytical instrument manufacturer.

HORIBA Green Hydrogen Solutions

Material Characterization - Solutions for Electrification Development and Testing by HORIBA

Application Laboratory Virtual Tour

Você tem alguma dúvida ou solicitação? Utilize este formulário para entrar em contato com nossos especialistas.