| Name | Process Laser Gas Analyzer |

| Model | PLGA-1000 |

| Messprinzip | NDIR: Nicht dispersives Infrarot |

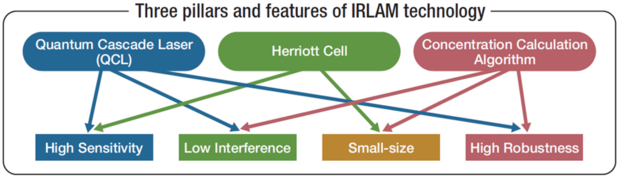

| Lichtquelle | QCL: Quantenkaskadenlaser |

| Laser Klasse | Klasse 1(IEC 60825-1:2014) |

[ Für C2H2-Konverter Eingang ]

| Komponenten*¹ | Acetylen (C2H2), Kohlenmonoxid (CO) |

| Messbereich | C2H2 : 0 - 10000 ppm, CO: 0 - 2000 ppm |

| Linearität | ±1.0 % Messbereichsendwert |

| Reaktionszeit | Td + T90 : 3 Sekunden bei 1.6L / min |

| Nullpunkt Drift | ±2.0 % Messbereichsendwert pro Monat |

| Spanpunkt Drift | ±2.0 % Messbereichsendwert pro Monat |

[ Für C2H2 Konverter Ausgang ]

| Komponenten*¹ | Acetylen (C2H2), Kohlenmonoxid (CO) |

| Messbereich | C2H2 : 0 - 10 ppm, CO: 0 - 10 ppm |

| Linearität | ±1.0 % Messbereichsendwert |

| Reaktionszeit | Td + T90 : 7 Sekunden bei 1.6L / min |

| Nullpunkt Drift | ±3.0 % Messbereichsendwert pro Monat |

| Spanpunkt Drift | ±3.0 % Messbereichsendwert pro Monat |

[ FÜr C2 Cracker Eingang ]

| Komponenten*¹ | Methan (CH4), Ethan (C2H6), Acetylen (C2H2), Kohlendioxid (CO2) |

| Messbereich | CH4 : 0 - 2000 ppm oder 0 - 5 vol% C2H6 : 0 - 50 vol% C2H2 : 0 - 50 ppm CO2 : 0 - 200 ppm |

| Linearität | ±1.0 % Messbereichsendwert |

| Reaktionszeit | Td + T90 : 3 Sekunden bei 1.6L / min |

| Nullpunkt Drift | ±2.0 % Messbereichsendwert pro Monat |

| Spanpunkt Drift | ±2.0 % Messbereichsendwert pro Monat |

[ Allgemein]

| Wiederholbarkeit | ±1.0 % Messbereichsendwert |

| Datenaktualisierungsrate | 1 Sekunde |

| Kalibrierintervall | 1 Monat |

| Umgebungstemperatur | -10˚C bis 50˚C oder -10˚C bis 45˚C (Keine direkte Sonneneinstrahlung, auch keine Einflüsse der Gehäusetemperatur durch Strahlungswärme und Wärmeleitung) *Die Durchflussmenge des Schutzgases unterscheidet sich je nach Vorgabe der Umgebungstemperatur |

| Ex-Zonen Einstufung | USA, Kanada: Klasse I, Division 2, Gruppen A, B, C, D T4 USA: Klasse I, Zone 2, AEx pzc IIC T4 Gc IECEx, Kanada: Ex pzc IIC T4 Gc ATEX, UKCA: |

| Schutzklasse | IP66、NEMA4X |

| Materialien in Kontakt mit dem Prozessgas | SS316, SS304, BaF2, FKM, PTFE, Au, Ni |

| Größe des Gasanschlusses | 1/4"NPT, 1/2"NPT (Option: N2 Generator) |

| Druckfehleralarm output | Drei Kanäle (Hauptgehäuse, optische Einheit, Zelle) DC 5 bis 24 V, 1 A pro Klemme |

| Kommunikationsfunktion | Modbus®/ TCP |

| Analog Ausgang | Vier Kanäle (Gaskonzentration) 4 bis 20 mA Max. Last: 550 Ω |

| Kontakt Ausgang | Drei Kanäle (Kalibrierung / Hauptalarm / Messung) Relaiskontaktausgang (isolierter Ausgang) DC 5 bis 24 V, 1 A an jeder Klemme |

| Digital Ausgang | Ein Kanal (für Signalbarriere-Leistungssteuerrelais) DC 24 V, 100 mA |

| Abmessungen | 664 mm (B) x 270 mm (T) x 704 mm (H) *Vorsprünge enthalten |

| Gewicht | Standard 46 kg, Max. 50 kg *Hängt von den Produktspezifikationen ab |

| Vesorgung | AC 100 bis 120 V, 50 Hz/60 Hz oder AC 200 bis 240 V, 50 Hz/60 Hz |

| Energieverbrauch | Max. 250 VA |

*¹ Bitte kontaktieren Sie uns für weitere Komponenten und Sortimente.

Modbus ist eine Marke von Schneider Electric USA Inc.