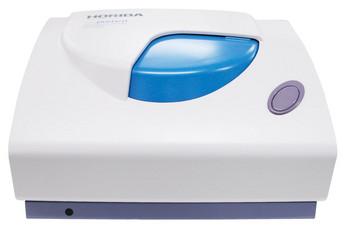

Laser scattering particle size distribution analyzer Model: LA-960V2

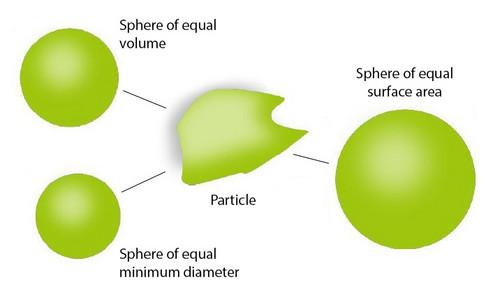

Measurement Principle | Mie scattering and Fraunhofer diffraction |

|---|---|

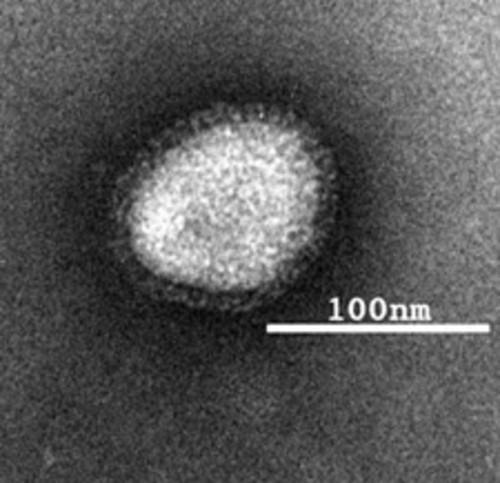

Measurement range | 10 nm - 5000 μm (Option dependent) |

Measurement Time | Typical measurement takes 60 seconds from liquid filling, sampling and measurement to rinsing. |

Measurement Method | Circulation measurement or fraction cell measurement (Fraction cell is optional) |

Sample Quantity | Approximately 10 mg - 5 g (Depending on the particle size, distribution and density) |

Dispersing Volume | Approximately 180 mL for standard pumping system, 5/10/15 mL for FractionCell accessory, Manual filling : 35 mL, Automatic filling : 40 mL for MiniFlow accessory. Approximately 1 L of LiterFlow option. |

Available carrier fluid | Aqua* (A type), Organic solvent (S type) (*Small volume ethanol can be used as a dispersing additive) |

Communication | USB 2.0 (USB3.0 required for some options) |

Light Sources | Red solid state 5 mW laser diode (650 nm), Blue solid state 3 mW LED (405 nm) |

Dispersion System | In-line ultrasonic probe: 30 W, 20 kHz, adjustable levels |

Operating Conditions | 15〜35°C (59 to 95°F), relative humidity 85% or less (no condensation) |

Power | AC 100-240V 50/60Hz, 300VA |

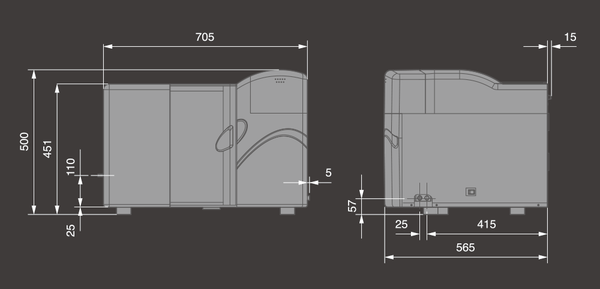

Dimensions | 705 (W) × 565 (D) × 500 (H) mm |

Mass | 54 kg |

Computer Requirements | PC operation, Software compatible with Windows® 10 64-bit and Windows® 11 64-bit, |

※Windows is a registered trademark of Microsoft Corporation in the United States and other countries.

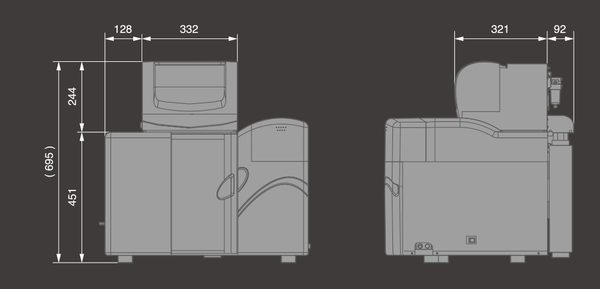

PowderJet Dry Feeder Accessory

Dispersion Method | Compressed air dispersion using Venturi nozzle |

|---|---|

Sample Delivery | Vibrating feeder |

Sample Disposal | Vacuum-driven evacuation |

Measurement range | 100 nm - 5000 μm |

Controls | Communication: Serial cable to LA-960V2 main unit |

Measurement Time | Typical measurement takes 2 seconds or longer. |

Operating Conditions for PowderJet | 15〜35°C (59 to 95°F), relative humidity 85% or less (no condensation) |

Dimensions | 332 (W) × 321 (D) × 244 (H) mm (not including dimensions of projections and LA-960V2 measurement unit) |

Power for PowderJet Operation | AC 100V, 120V, 230V, 50 or 60Hz, 1500VA (Including vacuum but LA-960V2 measurement unit) |

Compressed Air Supply Pressure | Compressed air supply origin pressure: 0.4 - 0.8 MPa |

Compressed Air Connection | Quick connector for resin tube with 6 mm outer diameter |

Remarks | Vacuum is equipped as standard |

※When ordering the PowderJet, please specify the power requirements for the final destination.

※Above specifications and functionality are valid only when PowderJet is installed on the LA-960V2 main unit and controlled using the LA-960V2 software.

※Manufacturers and models indicated for vacuum, air compressor, computer, monitor, and/or printer are subject to change.

◎Air Compressor

Inlet pressure within 0.5 - 038 MPa, Tank capacity 26 L or larger, Flow rate 45 L/min or faster

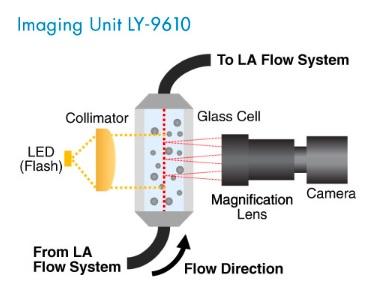

LY-9610 Imaging Unit

| Measureable Range for image analysis | 9 - 1000 μm |

|---|---|

| Pixel Size | 0.8 μm |

| Speed | ≧ 4 fps |

| Functions | Histogram of equivalent circle diameter. Shape Parameters: Aspect ratio*, Circularity*, Length*, Width* Trend graph of equivalent circle diameter. Post Analysis of captured image (zoom-in/out, measuring size). |

| Communication | USB 3.0 |

*Optional Advanced software

Accessories

| Components | LA-960N2 | LA-960A2 | LA-960S2 | LA-960W2 | LA-960L2 | |

|---|---|---|---|---|---|---|

| Optics | Standard optical system | • | • | • | • | • |

| Aqua type Ethanol can be used as a dispersing additive. (0.01 - 3000 μm) | Standard circulation system | - | • | - | - | - |

| Pressurized fill adapter | - | - | - | • | - | |

| Liter flow | - | - | - | - | • | |

| Peristaltic pump system | - | - | - | • | - | |

| Solvent type(0.01 - 3000 μm) | Standard pump system | - | - | • | - | - |

| Accessories | Fraction cell holder | • | • | • | • | • |

| Mini-Flow with ultrasonic unit (0.01 - 1000 μm) | • | • | • | • | • | |

| Paste cell holder | • | • | • | • | • | |

| Dry unit (0.1 - 5000 μm) | • | • | • | • | • | |

| Auto sampler | - | • | • | • | • | |

| High Concentration Cell | • | • | • | • | • | |

Imaging Analysis Unit | - | • | • | • | • | |

External Dimensions (mm)