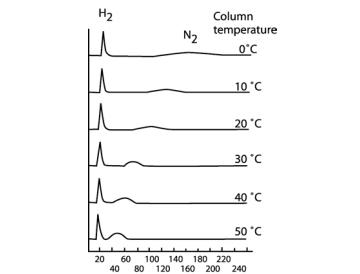

| Measurement target element | Hydrogen |

| Measurement gas type | H2 |

| Detector | TCD |

| Measurement range* *Up to 100% wt is possible by decreasing the sample weight | 0.04 ppm-0.02% |

| Precision / Repeatability | σn-1-≦0.04 ppm or CV≦0.5%(GAS) |

| Sample weight | 1.0 g* *Possible to decrease. |

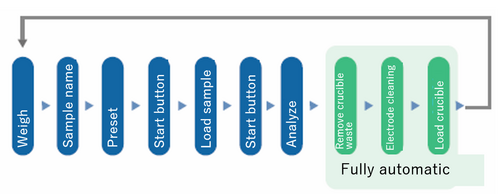

| Cycle time* *From the start of measurement to auto-cleaning and crucible supply. | Approx. 280 sec (According to our standard conditions) |

| Required gas | Carrier gas Ar: Purity greater than 99.995%, Pressure 0.35 MPa (Stainless steel tube O.D.3 mm and suitable connector fitting within 3 m from the unit) Operation gas Dry air or N2 as operating gas: Pressure 0.45 MPa (Nylon pipe O.D.Connection of φ6/4 mm nylon pipe within 5 meters of the main unit). |

| Dimensions* *Dimensions exclude pipework and other protrusions. | 655 x 710 x 725 mm [W x H x D] |

| Weight | Main unit: 197 kg (Furnace unit: approx.127 kg / Measurement unit: approx.70 kg) Cleaner unit: approx. 28 kg / Radiator unit: approx. 33 kg |

| Power | Main unit: AC 200/220/230 ±10% 50/60 ±1 Hz 12 kVA (MAX) Vacuum cleaner: AC 100V (Step-down transformer included) 50/60 ±1 Hz 1.5 kVA (MAX) |

Optional Units for Multiple Applications

Gas conversion unit (C-50) This unit converts the generated sample gas into a measurable gas (CO, N2, H2) using a gas reduction method.

| Capsule press machine (FP-30) The press machine for encapsulating powder samples ensures stable encapsulation without relying on operator skill.

| Auto sampler The press machine for encapsulating powder samples ensures stable encapsulation without relying on operator skill.

|

Halogen trap unit (HT-30) The unit enables efficient gas conversion with additional reagents, depending on the sample.

| Opening safety cover The safety cover unit with interlock function ensures operator safety.

| Additional detector unit for O / N* Sharing the extraction unit enables high-precision oxygen and nitrogen analysis, as well as ultra-trace hydrogen analysis.

|