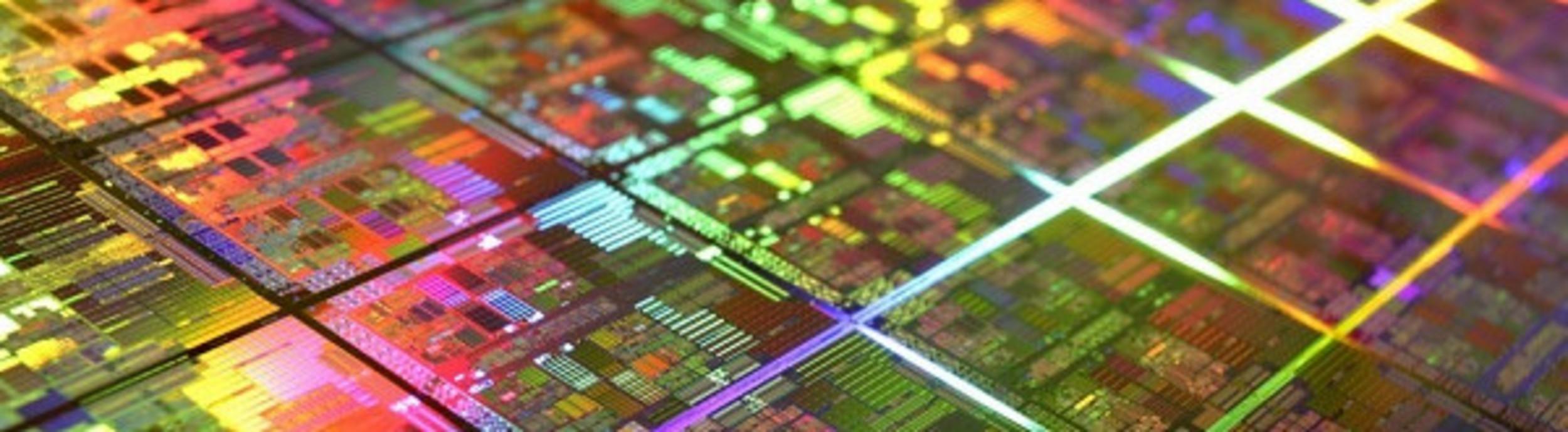

Many industry leaders in the power electronics space utilize Metal Organic Chemical Vapor Deposition (MOCVD) as a standard process for laser diode, LED, and semiconductor manufacturing. The MOCVD process is a recognized controllable synthesis method that uses a variety of precursors like Trimethyl Indium (TMI) and Diethyl Zinc (DEZ) that require a robust delivery method to ensure process repeatability and high yield. MOCVD systems utilize bubblers to vaporize the precursor allowing control of the precursor concentration, growth time, and growth rate. Some of the precursor is captured in the carrier gas stream and flows out of the bubbler to the chamber. The amount of captured precursor in the process must be known, and more than anything, must be repeatable to provide maximum efficiency. Achieving this requires accurate, fast, and ideally closed-loop control of process variables including gas flows, temperatures and pressure.

Advanced high-precision process control instrumentation for high yield MOCVD applications

HORIBA’s MOCVD product portfolio provides solutions for all variations of this delivery technique including high accuracy thermal mass flow controllers (MFC), electronic back-pressure controllers, and non-dispersive infrared spectroscopy (NDIR) concentration monitors that are proven for use in the most challenging precursor applications. HORIBA also offers an interferometry end point monitoring techniques that can be applied to critical process environments.

The optical system is made up of a light source, gas cell and double beam detectors. The stability of the double beam detector has been proven over a period of more than 40 years.

Do you have any questions or requests? Use this form to contact our specialists.