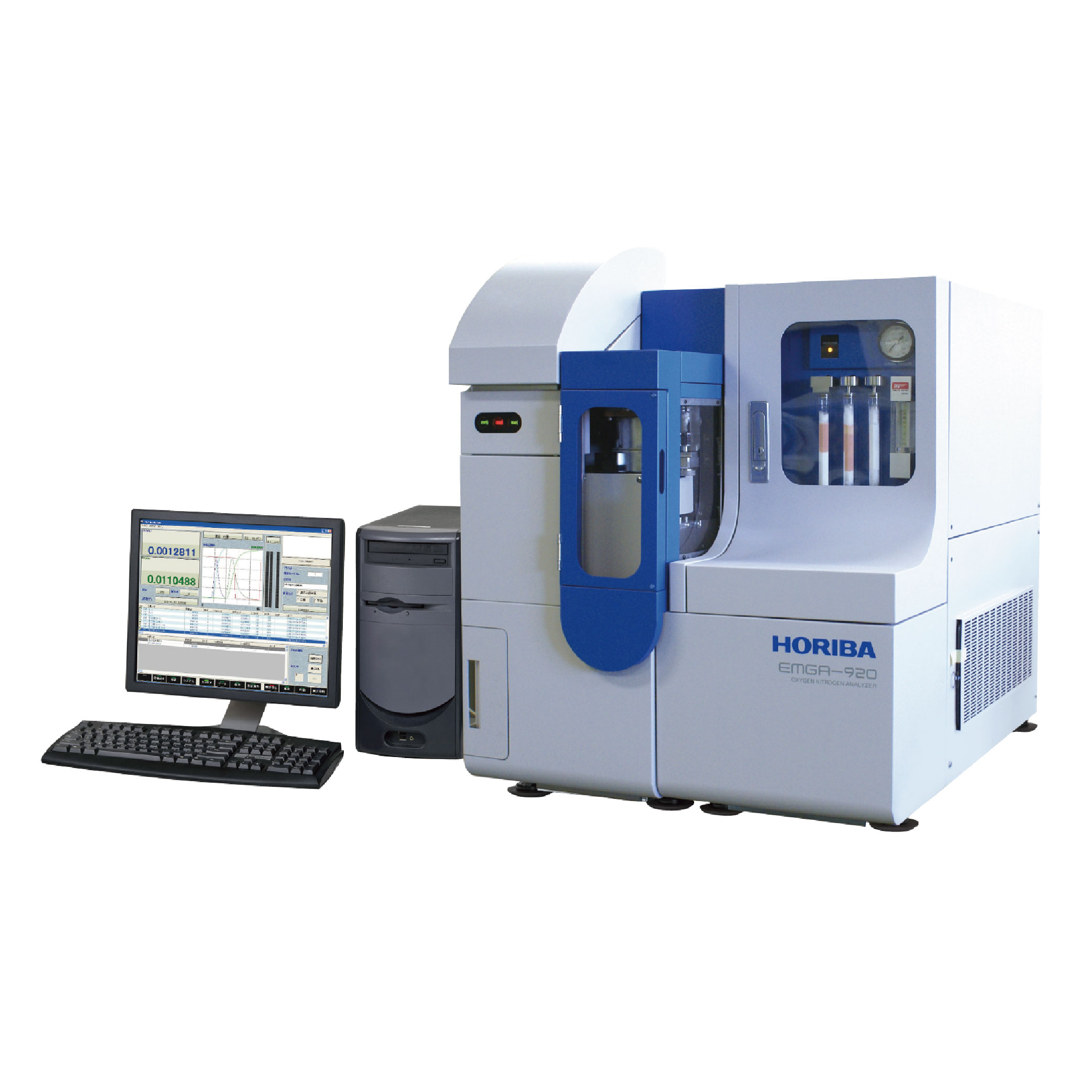

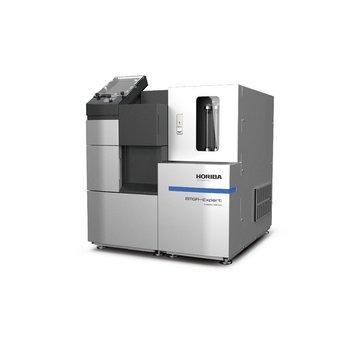

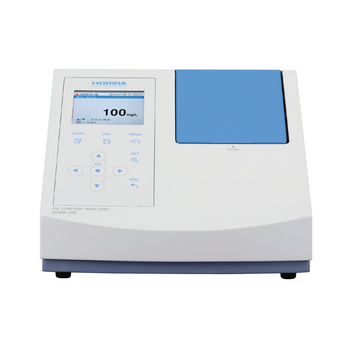

EMGA-920:Oxygen/Nitrogen analyzer

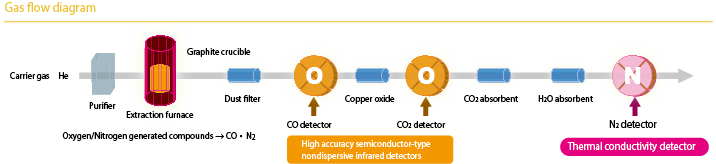

Principle

Oxygen:Non Dispersive Infrared detector

Nitrogen:Thermal Conductivity detector(TCD)

Measurement range*:

Oxygen:0-5%, Nitrogen:0-3%

*Up to 100% wt is possible by decreasing the sample weight.

Sample weight: 1,0 ± 0,1g

Sensitivity(Minimum reading): Oxygen/Nitrogen: 0.0000001%(m/m)

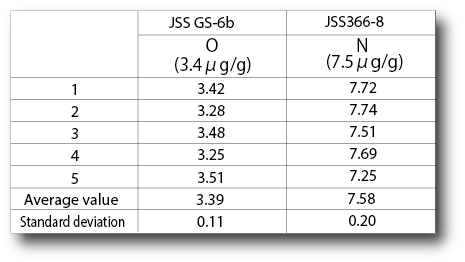

Accuracy**(Repeatability)

Oxygen/Nitrogen

σn-1≦0.02%(m/m) or CV≦0.5% whichever is larger (Reference gas)

σn-1≦0.3%(m/m) or CV≦1.0% whichever is larger (Standard sample)

** Based on the sample weight 1,0 ± 0,1g and with automation functions described below

Display

1) Measurement result: LCD or printout

2) Alarm message: LCD or printout

3) Flow sheet: LCD

Power of furnace

Iner gas fusion in impulse furnace

Enable to set the generating power 0 - 8,0kw

Sample introduction: Dual sample/flux introduction mechanism

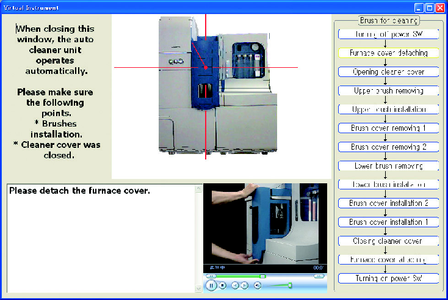

Automation functions: Auto cleaner, Crucible loader

Integration conditions:

Preset time integration

Integration up to reach comparator level

Preset time integration or integration up to reach comparator level, whichever is shorter

Sample ID: Enter up to 20 one-byte characters

Calibration

1) One point or multi point calibration (Reference gas or standard samples)

2) Calibration using previous analysis data

3) Calibration curve correction function

Functions

1) Display of realtime extraction curve

2) Analysis interruption

3) Self diagnosis and alarm display

4) Analysis of extraction curve (Superposition, difference etc analysis)

5) Out put (RC-232C or TCP/IP)

Dimensions: 750mm(H)×785mm(D)×653mm(W)

Sample introduction is positioned at 650mm from table.

Weight: 230kg

On carrying, it is devided in two units (Under 140kg/unit)

Computer: PC model operating OS Windows® XP(SP2) and beyond

Power

Main unit: AC200/220/230/240V ± 10%

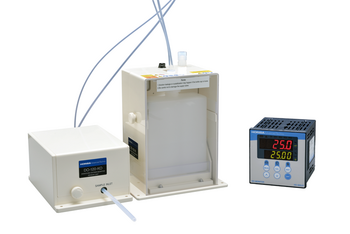

Auto cleaner: AC100V (Step-down transformer)

Frequency: 50/60 ± 1Hz

Electric power consumption

Main unit:12kVA (MAX)

Auto cleaner: 1.5kVA (MAX)

Ground resistance: Less than 10Ω

Installation condition

Operation temperature: 5-40°C

Performance temperature: 5-35°C

Humidity: Maximal relative humidity 80%RH between 5-31℃, Linearly decrease down to 50%RH between 31-40℃

Vibration: Duplex amplitude 20micron and less than 0.098m/S2 accelerations at frequency band

Required gas

He carrier gas: Purity greater than 99.995%, Pressure 0.35MPa

Stainless steel pipe(O.D.3mm) and suitable connecter fitting within 3m of unit

Dry air or N2 as operating gas: Pressure 0.45MPa

Nylon pipe(O.D.6mm) and suitable connecter fitting within 5m of unit

Cooling mechanism: Radiator unit (Separation type)

Electronic balance (Option)

Enable connection with electronic balance with 1-0,01mg minimum display

Optional automatic voltage regulator (AVR)

Capacity:15kVA

Weight: 130kg

This product has been discontinued and is no longer available. You can still access this page for informational service purposes.

This product has been discontinued and is no longer available. You can still access this page for informational service purposes.