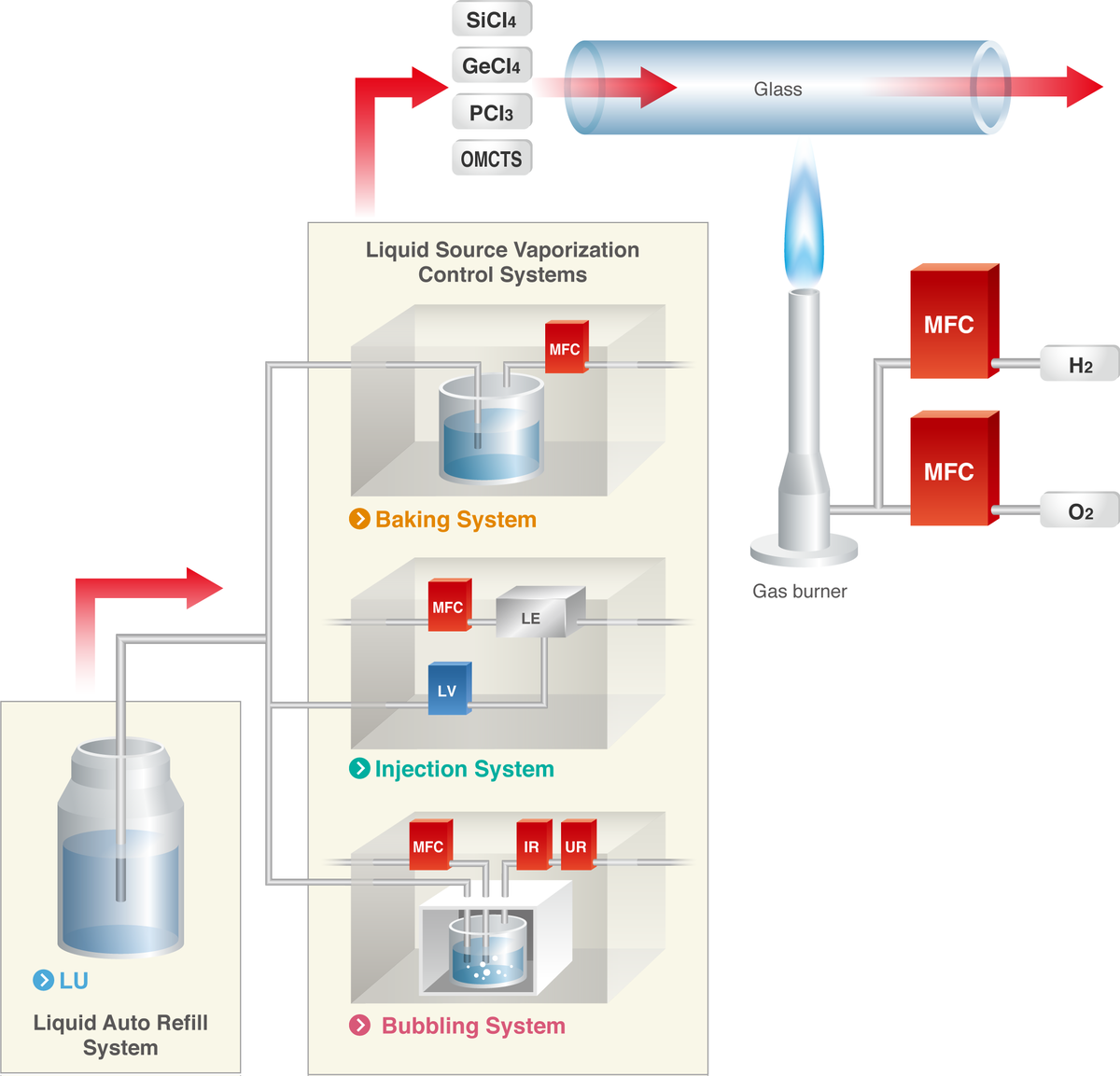

When manufacturing fiber optics, plasma torch gas control is critical to the process. HORIBA’s flow measurement and control technology is used to accurately and repeatedly control the flow rate of these gases. To create a preform, fiber optics manufacturers can use POCl3, SiCl4 and GeCl4 delivered via a bubbler system or hotbox. Precise and repeatable control of the vaporization process is contingent on the precise operation of the bubbler / hotbox and tight control of the carrier gas.

HORIBA’s flagship SEC-Z500X series which can control flows up to 500slm, combined with our high temperature SEC-8000 series MFC are the perfect solution for accurate flow control of these critical process gases.

Large Flow Liquid Source Vaporization Control System

Mixed Injection System Liquid Vaporizer

Digital Mass Flow Controller

High Temperature Digital Mass Flow Controller

Digital Liquid Mass Flow Meters / Controllers

Compact Baking System

Liquid Auto Refill System

Mixed Injection System Liquid Vaporizers

Direct Liquid Injection System

Multi Range/Multi Gas Digital Mass Flow Controller

Do you have any questions or requests? Use this form to contact our specialists.