Contributes to the reduction of environmental impact by Optical Smart Sensing

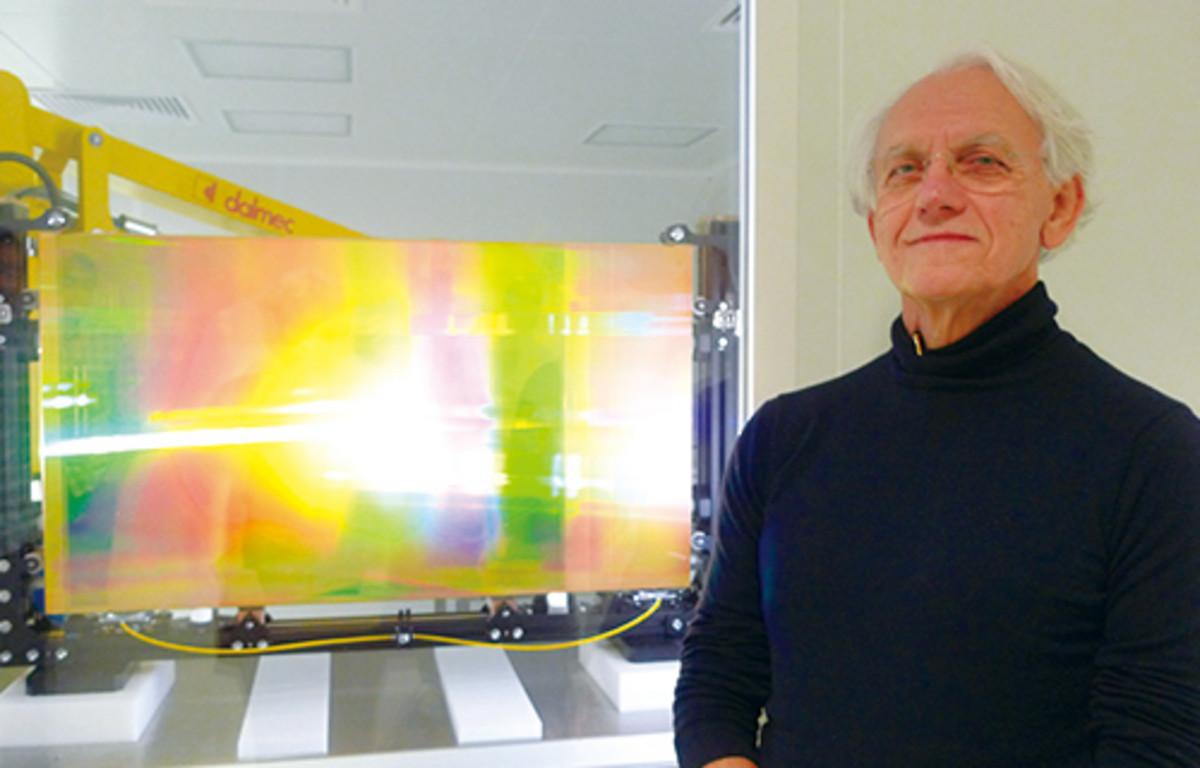

HORIBA offers a lineup of various monitoring systems that are incorporated into the wafer manufacturing process, which is essential for semiconductors.

The wafer manufacturing process uses a of gases, which are detoxified and released into the atmosphere at the end of the process.

In this process, there is a risk that the vacuum pumps and valves that draw the gases from the chamber may become blocked by by-products and become inoperable, and there is no established method to confirm that the gases have been rendered harmless.

In recent years, the global movement toward carbon neutrality has been accelerating, and the semiconductor industry has been changing its environmental awareness as well as improving device performance.

HORIBA's infrared absorption type concentration monitors (IR-400 series) monitor gas concentrations from chambers and vacuum pumps.

By constantly monitoring the cleaning state of the chamber and the concentration of by-products in the vacuum pump, it is possible to know the optimal timing for chamber maintenance and to prevent blockages of precision parts and sudden pump stoppages, thereby improving the efficiency and safety of the wafer fabrication process and It contributes to the reduction of environmental impact.