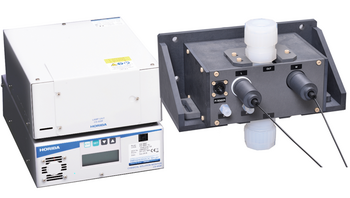

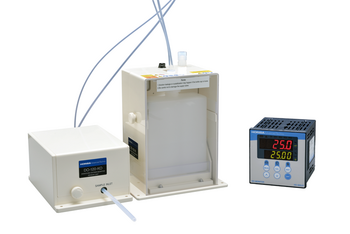

Indication converter specifications

| Model | HD-200FL |

|---|---|

| Measuring method | Optical (fluorescent) |

| Measuring range | DO: 0 to 20 mg/L Resolution: 0.01 mg/L Saturation: 0 to 200% Resolution: 0.1% Temperature: 0 to 50°C Resolution: 0.1°C |

| Repeatability | Within ± 1% of full scale |

| Linearity | Within ±2% of full scale |

| Transmission output | 2 points 4 mA to 20 mA DC output isolated type Maximum load resistance 900 Ω Range 1: DO concentration: Freely selectable within the measurement range Range 2: Temperature: Freely selectable within the range from -10.0 to 110.0°C Alarm: Burnout function (3.8 mA or 21 mA) Hold: Selectable from previous value hold, optional value hold |

| Contact output | 3 points Dry contact output Relay contact, SPDT (1c) Signal R1, R2: upper limit alarm, lower limit alarm, hold, Cleaning (selectable) FAIL : Alarm Control operation Control width: 0.02 to 4.00 mg/L (±0.01 to ±2.00 mg/L) |

| On cleaning output | 1 point Wet contact output (connecting power supply voltage output) Relay contact, SPST (1a) Contact function: Solenoid Valve Control |

| External input | 1 point Contact shape: Open connector dry ‘a’ contact Contact function: Cleaning Unit Control |

| Communication function | RS-485 2-line, insulated input/output (transmission output is not insulated) |

| Temperature compensation range | 0 to 50°C |

| Temperature compensation device | Thermistor |

| Calibration method | Atmosphere span calibration, zero liquid (sodium sulfite) calibration, span liquid (atmosphere saturation liquid) calibration |

| Self-diagnosis function | Calibration error, sensor diagnosis error, converter alarm |

| Operating temperature range | -20 to 55°C (Should not be frozen) |

| Power supply | 90 to 264 V AC 50/60 Hz Power consumption: 15 VA (max) |

| Structure | IP65 : 50 A pole or wall mounting Case: Aluminum alloy Mounting brackets, hood: SUS304 |

| Mass | Main unit body: Approx. 3.5 kg Hood, mounting brackets: Approx. 1 kg |

| Regulatory compliance | CE marking, FCC |

| Compatible sensor | DO-2000 |

*1 When extending the sensor cable, transmission cable, or contact input cable 30 m or more, the CE marking EMC directive surge test does not apply.

*2 An arrestor (inception voltage: 400 V) is mounted on the unit for transmission output, contact input, and communications. However, an optimal surge absorber should be installed on the connecting line depending on the surrounding environment, equipment setup, externally connected devices, etc.

Probe specifications

| Model | DO-2000 |

|---|---|

| Measurement principles | Optics (fluorescence) |

| Sample water | 0 to 50°C |

| Wetted material | SUS316、NBR、PVC |

| Response time | 90% response: Within 30 s 95% response: Within 60 s |

| Mass | Approx. 3.0 kg (incl. 10 m cable) |

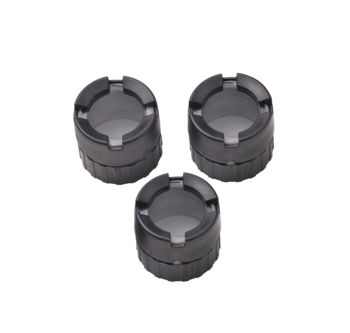

Sensor cap specifications (replaceable)

| Model | 5700 |

|---|---|

| Wetted material | NBR, PMMA |

| Mass | Approx. 5.0 g |

| Membrane memory | Built-in memory in the membrane unit, automatic recognition |