化学机械研磨(CMP)是一种强大的制造技术,它使用化学氧化和机械研磨以去除材料,并达到非常高水平的平坦度。化学机械研磨在半导体制造中被广泛应用于选择性去除材料以实现形貌的平坦和器件结构的形成。材料的选择性去除是通过使用化学反应和机械研磨与含有独特的化学配方和大量研磨颗粒的研磨液。研磨过程中会产生化学反应产物和机械磨屑。研磨液颗粒和研磨副产物压在晶圆表面。在晶圆从研磨设备转移到清洗设备的过程中,污染物会附着在晶圆表面。CMP后清洗需要去除不同表面、不同几何特征的化学和机械性能的晶圆上的颗粒、有机残留物和金属污染物,而不产生划痕、水渍、表面粗糙、腐蚀和介电常数的漂移。

Chemical mechanical polishing (or planarization) is the most popular technique for removing the surface irregularities of silicon wafers. Typical CMP slurries consist of a nano-sized abrasive dispersed in acidic or basic solution. A chemical reaction softens the material during mechanical abrasion. The abrasive particles have a size distribution which directly affects critical metrics including rate of removal and wafer defects. Particle size analysis is therefore a key indicator of CMP slurry performance.

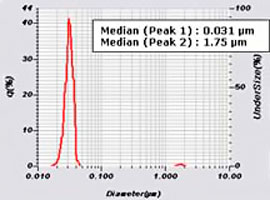

The typical size range of CMP abrasive particles is 50-250 nanometers and several particle sizing techniques are capable of measuring in this range with varying accuracy and precision. The typical oversize aggregate in CMP slurry is 1-10 microns and appears in the ppm range. The particle characterization challenge comes from the combination of accurately sizing the nano-scale particles while also identifying a relative few micron-scale aggregates.

Fine Particle Characterization in Chemical Mechanical Planarization (CMP) Slurries with Fluorescence Correlation Spectroscopy

with Prof. Edward E. Remsen | Bradley University, Mund-Lagowski Department of Chemistry & Biochemistry

and Tim Holt Applications Lab Manager | HORIBA Instruments, Semiconductor Segment

Fabrication of commercial integrated circuits depends critically on the physical and chemical properties of the abrasive slurry particles used to polish silicon wafer surfaces via chemical-mechanical planarization (CMP) to near-atomic flatness. The particle size distribution (PSD) of the abrasive particles is a key factor in the CMP process due to its connection with polishing efficiency and defect creation on wafers during polishing. In this presentation the utility of a single-molecule spectroscopic technique, fluorescence correlation spectroscopy (FCS), in this application is described. FCS stands out among PSD analysis methods based on its sensitivity to particles with hydrodynamic diameters in the sub-10 nm size range. Characterization of abrasive particles of smaller size in CMP slurries has become a requirement as the feature sizes of integrated circuits steadily decrease according to Moore’s law. The use of FCS in conjunction with a complementary technique, particle tracking using the Viewsizer 3000 multi-laser Nanoparticle Tracking Analysis (m NTA), is described as an approach to meet this challenge.

Laser diffraction is the most popular technique for sizing CMP slurries owing to its fast, accurate, and precise measurements of both the nano- and micro-scale particles. The LA-960V2 Particle Size Analyzer can accurately measure particles from 10 nanometers to 5,000 microns, making this system an obvious choice for CMP applications. Our recent study to quantify the ability of the LA-960V2 to find a small number of oversize particles in the presence of the main population at 31 nanometers proves this point.

In this webinar we will first review and discuss the importance of the iso-electric point of metal-oxide polishing agents and the role of slurry pH and then we will examine the effect of slurry fluid chemistry using ZP measurements to characterize the chemically-modulated development of surface charge of such polishing agents during aqueous polishing.

The SZ-100V2 Nanoparticle Analyzer system uses dynamic light scattering has one advantage over laser diffraction: the ability to measure sub-100 nanometer particles at very low sample loading (particle concentration). After the presence of any destructive large particles has been verified, CMP test labs may add a DLS system to complement existing technologies for characterization of the smallest particles.

先进原子力显微镜

纳米粒度及Zeta电位分析仪

蒸汽浓度监测仪

微量 pH 计

如您有任何疑问,请在此留下详细需求信息,我们将竭诚为您服务。